A voice recorder plush toy combines a traditional soft toy with an internal electronic module for recording and playback. From a manufacturer’s perspective, this type of voice recorder plush toy is a complex integration of textiles, electronics, and stringent safety protocols. For B2B buyers, it represents a powerful tool for creating products that forge a lasting emotional connection with the end consumer.

This guide provides an in-depth, factory-level perspective on the entire process, from initial concept to mass production and logistics.

The Market for Voice Recorder Plush Toys

The demand for interactive toys remains strong globally. A standard plush toy is a commodity; a voice recorder plush toy that carries a recorded message becomes a keepsake. This added value allows brands to command higher retail prices and build significant brand loyalty.

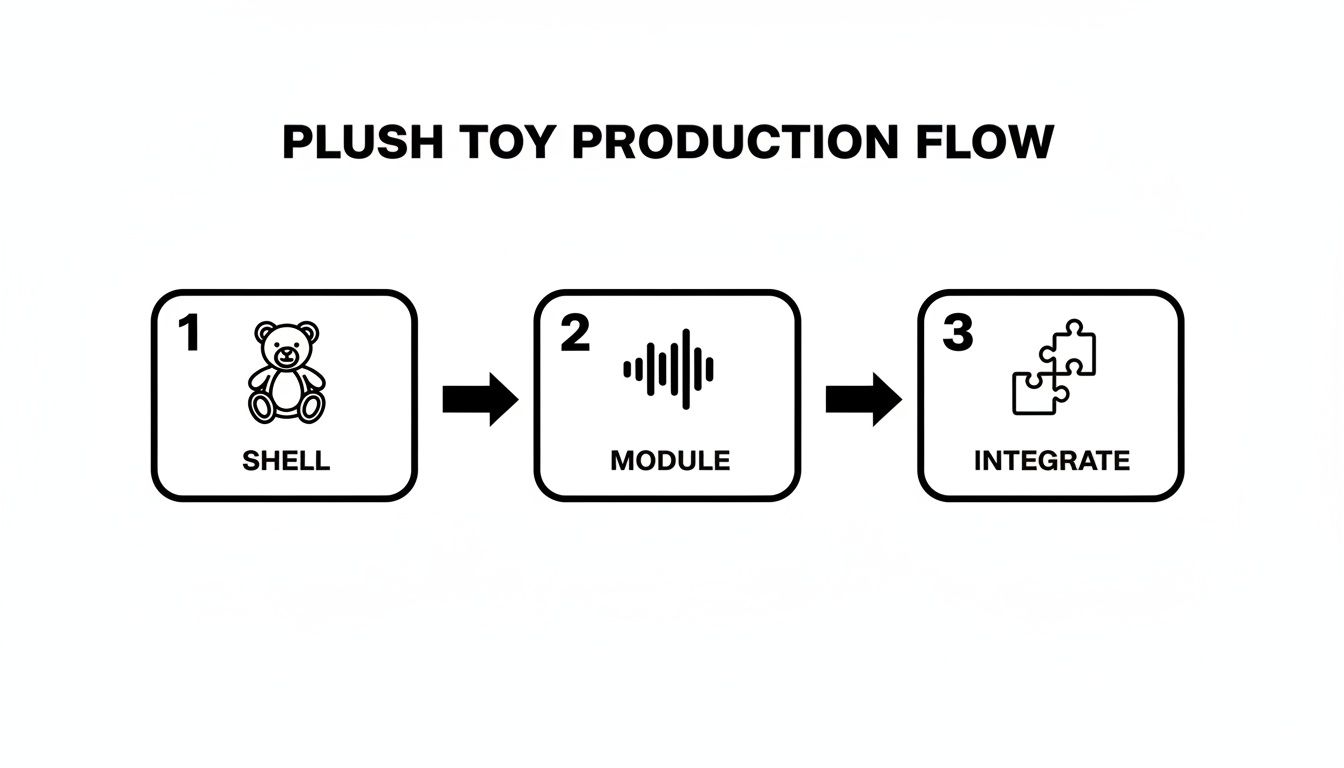

The core of the product consists of two primary components: the plush “shell” and the electronic voice module. Our role as a manufacturer is to seamlessly integrate these elements, ensuring tactile softness, structural integrity, and clear audio performance.

Commercial Applications

The versatility of this product opens up diverse B2B opportunities across various sectors:

- Retail Brands: Create signature characters with unique sounds or songs, fostering collectibility and brand identity.

- Corporate Gifting: Deliver personalized thank-you messages or company mottos to high-value clients in a memorable format.

- Healthcare & Wellness: Used in therapeutic settings for children or as comfort items for patients, carrying a loved one’s reassuring voice.

- Promotional Merchandise: Ideal for events, movie launches, or brand activations, pre-loaded with catchphrases or jingles.

This adaptability makes the voice recorder plush toy a strategic product with a high potential for return on investment. It is not just a toy; it is a compact, tactile communication platform.

The Manufacturing Process: A Factory Floor Perspective

Bringing a voice recorder plush toy from a 2D design file to a finished product is a multi-stage process honed over decades. Here at our Yiwu factory, we follow a rigorous workflow to ensure precision and quality at every step.

Step 1: Prototyping and Sampling

It begins when we receive your design file (typically an AI or PDF). Our pattern master, a highly skilled artisan, translates your 2D artwork into a 3D fabric pattern. This is a critical stage where millimeters matter—an incorrect seam placement can alter a character’s entire expression. Getting the pattern right is paramount.

Once the pattern is approved, we move to material sourcing and cutting. Large sheets of the selected plush fabric are laid out, and the pieces are cut with precision, either by industrial die-cutting machines for volume or by hand for intricate shapes.

Typical Sampling Timeline: 5-10 working days. This period is for creating the initial physical sample and allows you to review and request revisions.

Step 2: Pre-Assembly and Embroidery

Before the main assembly, details like embroidered eyes, logos, or other features are applied while the fabric pieces are still flat. This ensures a clean, high-quality finish that is difficult to achieve on a stuffed, three-dimensional object.

Step 3: Assembly, Stuffing, and Module Integration

Our sewing team then stitches the fabric pieces together, leaving a small, strategically placed opening for stuffing. This is where the product takes its shape.

The plush shell is then filled with hypoallergenic PP (polypropylene) cotton. We carefully control the stuffing density to achieve the desired balance between softness and structural form. Immediately after, the pre-tested voice recorder module, housed in a protective cloth pouch, is inserted. The final opening is then hand-sewn with an invisible stitch to create a seamless finish.

A common oversight by new buyers is underestimating the importance of module placement. It must be positioned for clear audio projection and easy activation without creating a hard, unappealing lump. This is always finalized during the physical sampling stage.

Typical Mass Production Timeline: 20-30 days after final sample approval. This can vary based on order volume and complexity.

You can learn more about the general workflow in our detailed guide on making plush toys.

Pricing Factors: What Drives Your Per-Unit Cost

Two questions dominate every initial buyer inquiry: “What is the per-unit cost?” and “What is your Minimum Order Quantity (MOQ)?” The answer is always determined by your specific project requirements.

Key Cost Drivers

Understanding these factors is crucial for managing your budget effectively.

- Materials & Filling: Standard short-pile plush is the most cost-effective. Premium materials like long-pile faux fur, minky fabric, or custom-dyed textiles increase the cost. The filling is typically PP cotton, but options exist.

- Size & Complexity: A larger toy requires more material, filling, and labor. A simple, spherical character is far less expensive to produce than a complex one with distinct limbs, clothing, and multiple embroidered elements. Every additional seam adds to the labor cost.

- Voice Module Specifications: The electronics are a significant cost component. A basic 10-second, playback-only module is inexpensive. Costs rise with features like longer recording times (e.g., 60+ seconds), re-recordable functionality, or higher-fidelity speakers.

- OEM vs. ODM:

- OEM (Original Equipment Manufacturer): You provide a complete, ready-to-manufacture design. This is generally lower cost as R&D is complete.

- ODM (Original Design Manufacturer): You choose one of our existing plush designs and customize it with your branding and voice module. This can be faster and more cost-effective for new brands.

A tip from the factory floor: Adding a “simple” accessory like a branded t-shirt can introduce 5-6 new production steps (pattern cutting, sewing, printing, dressing the toy), significantly impacting labor costs. Buyers often underestimate this.

Understanding Minimum Order Quantities (MOQ)

MOQ is not an arbitrary number; it is dictated by the economics of production. There are fixed setup costs for fabric cutting dyes, embroidery machine programming, and material procurement.

- Typical MOQ Range: 500–1,000 pieces is a common starting point for semi-custom designs using standard materials and existing voice modules.

- Higher MOQs (3,000+ pieces): This is often required for projects involving custom-milled fabrics or fully bespoke electronic modules, as our component suppliers in Shenzhen have their own MOQs to cover their engineering setup costs.

Quality Control and Global Safety Standards

For a product intended for children, quality control and safety are non-negotiable. A faulty product is not just a commercial risk; it’s a direct threat to your brand’s reputation and consumer safety. Adherence to international standards is a cornerstone of our manufacturing process.

Key Safety Standards: EN71 & ASTM F963

If you plan to sell in Europe or the United States, your product must comply with these standards.

- EN71 (European Union): The primary safety standard for toys sold in the EU. It covers mechanical properties, flammability, and chemical composition.

- ASTM F963 (United States): The mandatory safety specification for toys in the US. It includes rigorous tests for choking hazards, sharp points, and material toxicity.

For a voice recorder plush toy, a key requirement under both standards is that the battery compartment must be secured with a screw to prevent access by children.

Our Multi-Stage Inspection Process

We implement a rigorous, multi-stage QC process to mitigate risks and ensure compliance.

- Incoming Material Inspection (IQC): All raw materials (fabric, thread, voice modules, stuffing) are inspected upon arrival for defects, color accuracy, and compliance with safety certificates.

- In-Process Quality Control (IPQC): Supervisors conduct checks at key assembly stages, verifying seam strength, embroidery quality, and correct placement of the voice module.

- Final Quality Control (FQC): Every finished unit undergoes a 100% inspection. This includes a visual check for aesthetic flaws, a functional test of the voice recorder, a pull test on attachments (eyes, buttons), and a final pass through a metal detector to ensure no stray needles are present.

The most significant risk for buyers is choosing a factory based on the lowest price. Low-cost suppliers often cut corners on material testing or QC checkpoints. This can lead to catastrophic failures, such as product recalls or shipments being seized at customs.

Logistics and Shipping

Once production is complete and has passed final inspection, the final stage is logistics. We handle packaging according to your specifications—from simple polybags to custom-printed retail boxes. We then coordinate with freight forwarders for shipment via sea or air, providing all necessary documentation (Bill of Lading, Commercial Invoice, Packing List) for customs clearance in your destination country.

How to Choose the Right Manufacturing Partner

Selecting a supplier is the most critical decision in this process. A cheap quote from an inexperienced factory can quickly become expensive due to delays, quality issues, or safety failures.

Vetting a Potential Supplier

Look for a manufacturer with demonstrable expertise in integrating electronics into plush products.

- Specialized Experience: Ask for a portfolio of previous electronic toy projects. Do they understand battery safety, module housing, and sound engineering for clear audio?

- Communication: Is their communication clear, professional, and timely? A responsive sales contact is often indicative of a well-managed operation.

- Transparency: A reputable factory will be transparent about its production process and willing to provide updates. A common problem buyers face is a lack of transparency, leading to surprise delays.

- Audits and Certifications: Ask if they have certifications like BSCI or ISO 9001. These demonstrate a commitment to ethical practices and quality management.

Key Questions to Ask Potential Suppliers

- Can you provide recent EN71 or ASTM F963 test reports for similar products? This validates their claims of compliance.

- What is your specific QC process for the electronic modules? They should test modules upon arrival and again after installation.

- What are your payment terms? The industry standard is a 30-50% deposit, with the balance due upon completion or after a third-party inspection. A demand for 100% upfront is a major red flag.

- How do you manage potential production delays or quality issues? A good partner has a clear problem-solving protocol and communicates proactively.

Choosing the right partner mitigates risk. A reliable manufacturer delivers not just a product, but also expertise, quality assurance, and peace of mind. Check our compliant stuffed animals to see the quality we deliver.

Why FunEnjoy is a Trusted Manufacturer

For over three decades, FunEnjoy PlushToys has been a leading manufacturer in Yiwu, the heart of China’s plush toy industry. Our 2,000㎡ facility and team of 200 skilled craftspeople specialize in complex projects, including the voice recorder plush toy. We combine traditional craftsmanship with modern technical expertise to deliver safe, high-quality, and innovative products for global brands. We understand the nuances of both plush manufacturing and electronics integration, making us a reliable partner for your next project.

Ready to bring your own custom voice recorder plush toy to life? With over 30 years of manufacturing experience, FunEnjoy PlushToys has the expertise to guide you through every step, from design to delivery. Contact us for a free quote today!