Bringing a character from a 2D drawing to a 3D, huggable plush toy is a complex manufacturing journey. It's a precise, collaborative process that blends creative vision with industrial-level technical skill. As a plush toy factory in China since 1993, we've guided countless brands through this process, from initial concept to mass production. This guide offers our B2B clients an insider's look at what it truly takes.

The Journey From Sketch to Stuffed Toy

The Plush Toy Market: A Global Overview

The demand for custom plush toys is not just growing; it's a significant segment of the global toy industry. A huge part of this industry is centred in China, where manufacturing hubs like ours have been crucial to this growth. China's toy market alone is set to expand from roughly $56.28 billion in 2022 to an estimated $78.21 billion by 2027, with a steady annual growth of 6.80%. You can dig deeper into these toy market trends in China for more context. For brands, this represents a massive opportunity to capitalize on unique IP and character-driven merchandise.

Benefits of Custom Plush Toys for Brands

For brands, IP holders, and businesses, custom plush toys are a powerful tool. They are more than just merchandise; they are tangible brand ambassadors.

- Strengthen Brand Connection: A physical character creates a deeper emotional bond with your audience.

- High-Margin Product: Well-designed plush toys can command premium pricing, offering excellent profit margins.

- Diversify Revenue Streams: They open up new retail and direct-to-consumer sales channels.

- Marketing Asset: Plushies serve as excellent promotional tools, social media content drivers, and event giveaways.

Types of Plush Toy Manufacturing: OEM vs. ODM

From a manufacturer's point of view, projects fall into two categories: OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer). Understanding the difference is critical for your business strategy.

- OEM is the most common route for brands. You provide a completely unique design—your own character, your IP—and we act as your manufacturing partner, engineering it precisely to your specifications. You retain full creative control and ownership.

- ODM involves selecting a pre-existing design from our catalog and customizing it with your branding, such as a logo or specific colors. This is often a faster, more cost-effective option for promotional items when a unique character design is not required.

The vast majority of our partners engage us for OEM services, ensuring their product is 100% unique to their brand.

The Manufacturing Process: From Tech Pack to Production

A successful production run is built on a foundation of clear technical specifications and a meticulously managed workflow. Here is the step-by-step process we follow to turn drawings into plush toys.

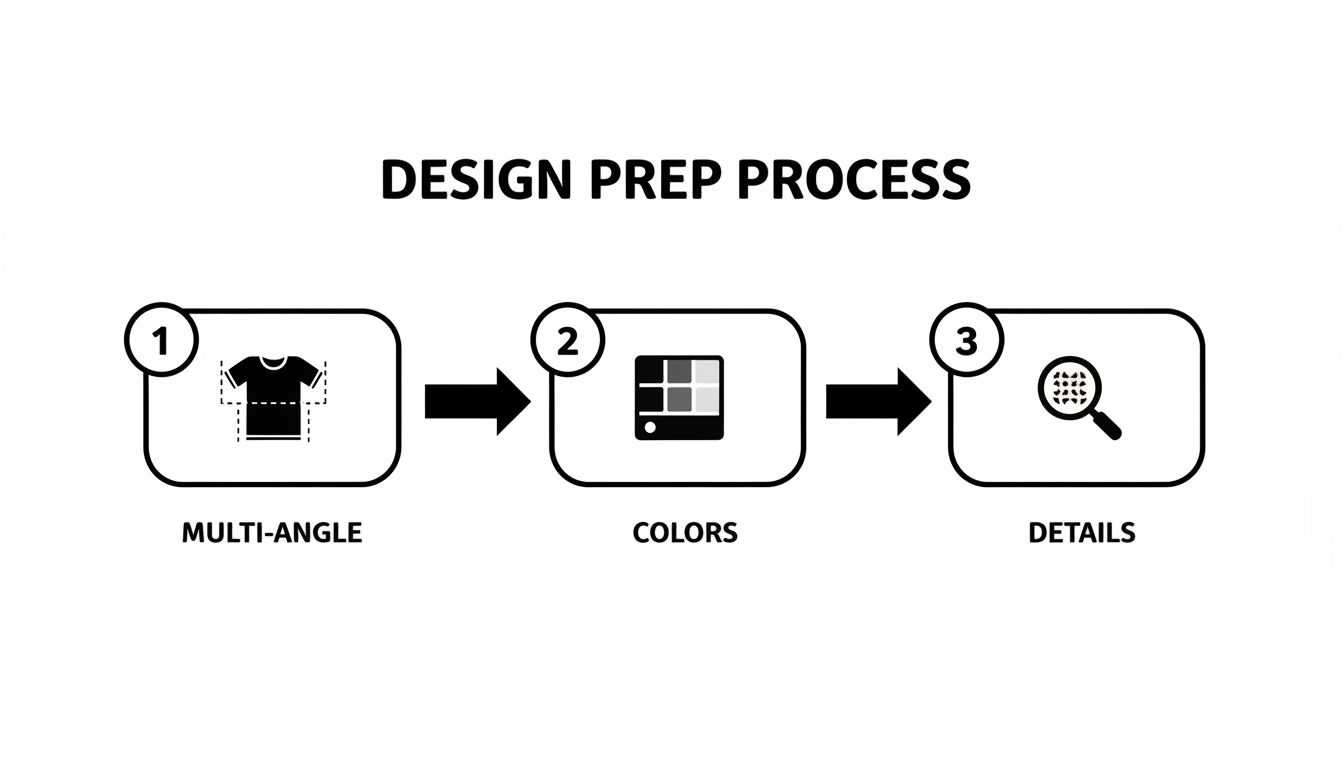

Step 1: Design & Technical Specification (Tech Pack)

It starts with your design, but a simple sketch is not enough. To minimize errors and accelerate sampling, we require a detailed design brief, often called a "tech pack." A single, front-facing drawing is a common starting point for clients, but it lacks the data our pattern makers need.

A production-ready design must include:

- Turnaround Views: Front, back, and both side views are non-negotiable. These are essential for creating a 3D pattern with accurate proportions.

- Color & Material Callouts: Specify all colors using the Pantone Matching System (PMS). Notes like "Body: Short-pile minky fabric (Pantone 123 C)" and "Eyes: Embroidery (Pantone Black 6 C)" eliminate guesswork and ensure brand consistency. This level of detail can cut sampling time in half.

- Construction Details: Specify embroidery vs. printing, stuffing density (e.g., firm body, soft limbs), and placement of any special components like plastic safety eyes or internal squeakers.

Step 2: Prototyping & Sampling

This is where your 2D design becomes a physical object. The sampling timeline is typically 5 to 10 working days.

- Pattern Making: Our master craftspeople translate your 2D views into a series of flat fabric patterns—the blueprint for the 3D toy.

- White Sample: Often, we first create a mock-up from plain fabric to perfect the shape, size, and construction without the distraction of colors. This allows for structural feedback before committing to final materials.

- Full-Color Sample: Once the form is approved, we create the full prototype using the specified Pantone-matched fabrics, embroidery, and finishes.

This sample is then shipped to you for review. Your feedback must be precise. "The arm looks weird" is not actionable. "Rotate the left arm forward by 10 degrees and shorten by 1cm" is feedback our team can implement immediately. The final approved sample becomes the "golden sample"—the quality standard for mass production. For a deeper dive into this initial process, you can learn more about how to design your own plush toy on our website.

Step 3: Material Sourcing & Mass Production

With the golden sample approved, we move to full-scale production, which typically takes 20-30 days.

- Material Procurement: We order all fabrics, threads, and stuffing in bulk based on your approved sample.

- Cutting & Embroidery: Fabric is cut into pattern pieces using precision dies, and details like eyes or logos are embroidered by automated machines.

- Sewing & Assembly: Skilled workers stitch the pieces together, turning the flat fabric into the 3D toy.

- Stuffing & Finishing: The plush is filled with the specified material (e.g., PP cotton, weighted beads) to the correct density.

- Final Inspection: Each unit undergoes a final quality check before being packaged.

For a deeper dive, we have a complete guide that covers more about how to make a plush doll which you might find helpful.

Pricing Factors: What Impacts Your Cost?

"How much will each plush cost?" The answer is always custom-quoted based on several key factors. There is no standard price list.

- Materials: The fabric choice is a primary driver. Standard short-pile plush is more economical than premium, long-pile minky or custom-dyed materials. Filling also matters; standard PP cotton is the baseline, while recycled or weighted fillings increase cost.

- Size: Larger toys require more material, stuffing, and labor time, directly increasing the unit cost.

- Complexity: A simple, spherical character is far less labor-intensive than one with intricate clothing, multiple limbs, and detailed embroidery. Every additional pattern piece and stitch adds to the cost.

- Order Quantity: This is the most significant factor. Larger orders allow for bulk material purchasing and production efficiencies, which dramatically reduces the per-unit cost.

Tip to Reduce Cost: If an initial quote is above budget, we can collaborate on solutions. Simplifying a complex embroidery pattern, slightly reducing the size, or choosing an alternative (but still high-quality) fabric are common ways to lower costs without compromising the core design.

Minimum Order Quantity (MOQ)

The MOQ is the minimum number of units a factory can produce in one run. Many large factories require orders in the thousands, creating a barrier for independent creators and new brands.

We maintain a flexible MOQ, typically starting between 100 and 500 pieces. This enables emerging brands to test the market without a prohibitive upfront investment. The global appetite for stuffed animals is huge, with forecasts suggesting the market could jump from USD 13.71 billion in 2025 to USD 26.23 billion by 2033. Since China produces roughly 85% of the toys sourced by the U.S., our ability to offer low MOQs gives new IP owners a crucial foothold in this growing space. You can read more about this in the global toys market analysis and forecast.

Be aware that a lower MOQ results in a higher per-unit cost. We provide tiered quotes showing how the price decreases as volume increases, allowing you to make an informed business decision. For those ready to scale up, looking into options for plush toys wholesale can offer even more insight into bulk pricing.

Quality Control & Safety Standards

Quality control is not a final step; it's integrated throughout our entire production process. A low-cost quote from a less reputable factory often means they are cutting corners on QC, posing a risk of inconsistent product quality, failed safety tests, and damage to your brand reputation. With China producing 70% of the world's toys, robust quality systems are non-negotiable. You can get a deeper look into China's massive toy industry to understand the scale.

Our Multi-Stage Inspection Process:

- Incoming Quality Control (IQC): We inspect all raw materials upon arrival for defects, color accuracy against Pantone specifications, and safety compliance.

- In-Process Quality Control (IPQC): Our line managers conduct spot-checks during assembly to catch issues like poor stitching or misaligned embroidery early.

- Final Quality Control (FQC): Before packaging, every single unit is inspected for common defects like open seams, asymmetry, incorrect stuffing density, and embroidery flaws. We also conduct needle detection scans.

Mandatory Safety Standards: EN71 & ASTM F963

If you intend to sell in Europe or North America, safety compliance is law. We design and manufacture every toy to meet these critical standards.

- EN71 (Europe): The EU standard for toy safety, covering physical and mechanical properties (e.g., choke hazards), flammability, and chemical restrictions (e.g., lead, phthalates).

- ASTM F963 (USA): The mandatory safety standard for toys in the United States, outlining requirements for materials, construction, and labeling.

We manage the third-party lab testing process (with accredited labs like SGS or Intertek) to provide you with the official compliance certificates required for legal retail.

How to Choose a Supplier

Choosing the right factory is the most critical decision you will make. A true manufacturing partner will provide transparency, expert guidance, and a commitment to quality. The risk of choosing a low-quality factory includes receiving a product that doesn't match the sample, failing safety tests, and experiencing costly delays.

Key Vetting Criteria for B2B Buyers:

- Portfolio & Specialization: Review their past work. Do they have experience with toys of similar complexity and materials to your own?

- Safety Compliance Record: Ask for proof of previous EN71/ASTM compliance certificates. A reputable factory will have these readily available.

- Communication & Expertise: Is their team responsive, professional, and fluent in your language? Do they ask intelligent questions about your design to prevent future problems?

- Factory Audits: A reliable supplier will be open to third-party factory audits (like BSCI or Sedex) which verify ethical labor practices and quality management systems.

A partnership thrives on mutual respect and shared goals. The right manufacturer invests in your success because they see it as their own. They provide solutions, not just products.

Why FunEnjoy is a Trusted Manufacturer

For decades, FunEnjoy PlushToys has been a reliable B2B partner for brands looking to turn drawings into plush toys. Our expertise is built on a foundation of technical skill, transparent communication, and an unwavering commitment to quality and safety. We understand the challenges brands face and have structured our processes to mitigate risk and ensure a smooth path from concept to market. Our flexible MOQs and deep knowledge of international safety standards make us an ideal partner for both emerging and established brands.

Ready to bring your character to life? The team at FunEnjoy PlushToys has the expertise and manufacturing know-how to transform your creative vision into high-quality, market-ready plush toys. Start your project with us today!