A plush toy keychain is more than a miniature accessory. From a manufacturing perspective, it is a highly engineered product designed for brand promotion, merchandising, and collectible markets. It combines the tactile appeal of a plush toy with the utility of a keychain, creating a high-margin, low-cost product perfectly suited for retail, corporate giveaways, and brand IP expansion. We have seen this category evolve from a simple add-on to a core strategic asset for global brands.

Why Plush Keychains Are a Merchandising Powerhouse

To understand the commercial value of plush toy keychains, one must look beyond their size. For IP holders, global brands, and retailers, these items represent a convergence of collectibles, fashion accessories, and marketing. They are not simply toys; they are sophisticated commercial products engineered for profitability and brand visibility.

The success is rooted in a compelling manufacturing and economic formula. A plush keychain’s small size and light weight significantly reduce international shipping and logistics costs compared to larger merchandise. This logistical efficiency is what allows brands to achieve a healthier profit margin per unit.

The Power of Portability and High Perceived Value

A plush keychain functions as a portable brand ambassador. When a customer attaches one to their backpack, keys, or handbag, it becomes a public display of brand affinity. This transforms a one-time purchase into continuous, organic advertising that travels with the consumer.

Furthermore, a well-manufactured plush keychain has a perceived value far exceeding its production cost. Quality materials, precise embroidery, and a pleasant tactile feel create the impression of a premium collectible, despite a low unit cost. This provides an accessible entry point for fans to purchase a piece of their favorite brand without the higher price commitment of a larger item.

As manufacturers, we see this firsthand. A brand might sell a large plush doll for $30, but a keychain version can sell for $10, despite costing a fraction to produce and ship. This accessibility broadens the customer base and drives impulse purchases right at the checkout counter.

Tapping into Global Collectible Trends

The demand for these items is not accidental. Here in China, plush toy keychains sit at the intersection of two major consumer trends: the thriving toy market and the global pop-collectible culture. The toy market in China is a multi-billion dollar industry, with stuffed toys as a leading category. A plush keychain is now part of a rapidly expanding, design-driven collectible ecosystem. You can discover more insights about the Chinese toy market for a deeper analysis.

Ultimately, brands leverage plush toy keychains for several strategic reasons:

- Low-Risk Market Entry: They are an excellent vehicle for testing new character designs or IP without significant financial investment.

- High-Margin Sales: The cost-to-retail price ratio is exceptionally favorable, enhancing overall profitability.

- Customer Loyalty: They serve as effective tangible rewards, gifts-with-purchase, or loyalty program incentives that strengthen the customer-brand relationship.

Deconstructing the Plush Toy Keychain: Materials & Components

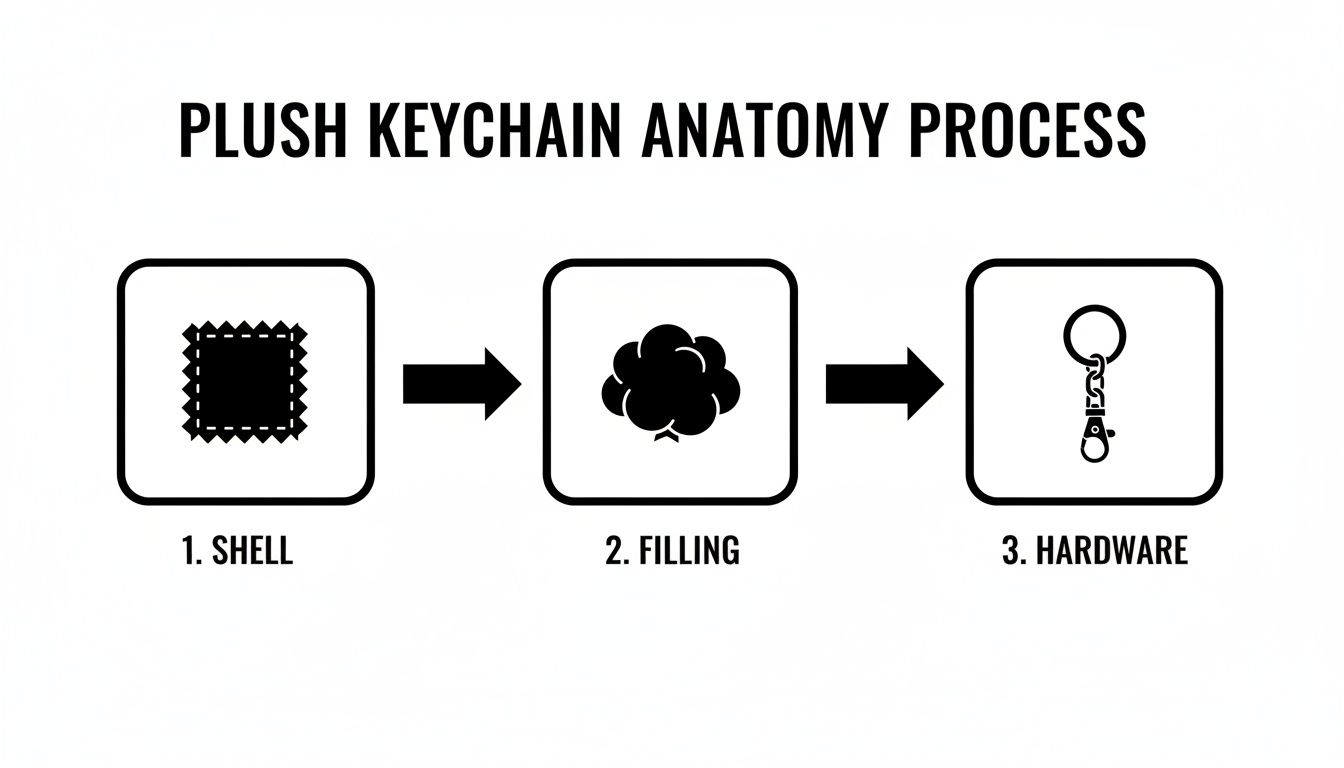

To effectively communicate your vision to a manufacturer, it is essential to understand the technical language of production. This begins with the core components of a plush toy keychain. Every material choice, from the fabric’s texture to the clasp’s metal finish, impacts the final product’s aesthetics, durability, and cost.

Consider it like providing an engineering schematic. The more precise the specifications, the more accurately we can execute the design. A plush keychain is fundamentally composed of three elements: the outer material (shell), the inner filling, and the hardware.

The Outer Shell: Material Selection

The outer shell is the primary tactile and visual component. The choice of material is critical in defining the keychain’s character and perceived quality. While countless fabrics exist, a few are industry standards due to their performance and reliability.

Crystal Super Soft Plush: This is the most common choice for most projects. It features a very short, dense pile that provides an exceptionally smooth, velvety feel. Its surface is an ideal canvas for high-stitch-count embroidery or fine-detail printing, making it the preferred material for character designs requiring crisp facial features.

Sherpa Fabric: For designs intended to be “cozy” or “cuddly,” sherpa is the optimal choice. It mimics the texture of wool with a classic fluffy, curly pile, commonly used for teddy bears or plush sheep. While its texture is inviting, its uneven surface is not suitable for fine embroidery.

Velboa: Velboa is a durable, short-pile faux fur with a subtle sheen. It is a workhorse material that provides a sleek, animal-fur appearance without the long fibers or higher cost of other faux furs. It is a cost-effective solution for achieving a high-quality look.

When specifying materials for your custom plush keychain, this comparison can guide your decision.

Material and Filling Options Comparison

This table outlines the most common material choices, helping you align the right components with your design intent and budget.

| Component | Material Type | Key Characteristics | Best For |

|---|---|---|---|

| Outer Shell | Crystal Super Soft Plush | Short, dense pile; smooth, velvety feel. | Detailed embroidery, character designs, and a premium feel. |

| Outer Shell | Sherpa Fabric | Fluffy, wool-like, and cosy texture. | Teddy bears, sheep, llamas, or any “cuddly” creature design. |

| Outer Shell | Velboa | Short-pile faux fur; durable with a slight sheen. | Cost-effective animal designs needing a sleek, fur-like look. |

| Filling | PP Cotton | Lightweight, hypoallergenic, holds shape well. | The industry standard for a classic, squishy plush feel. |

| Filling | Foam Particles | Denser, heavier, bean-bag-like feel. | Stress-ball style keychains or products with a unique sensory feel. |

The right combination of materials is the first step in creating a product that not only looks correct but also delivers the intended tactile experience.

The Filling: Internal Composition

The internal filling is as critical as the external shell. It determines the keychain’s density, weight, and compression recovery (its “squishiness”). This is a key quality indicator for the end-user.

The industry standard is Polypropylene (PP) Cotton. This synthetic fiber is lightweight, hypoallergenic, and exhibits excellent resilience, bouncing back to its original shape after repeated compression. It provides the classic, satisfying softness expected from a plush toy.

For a distinct sensory experience, some designs utilize foam particles or memory foam. These materials create a denser, heavier product with a feel similar to a high-end stress ball. While this provides a unique tactile quality, it increases the unit cost and is typically reserved for premium projects. Understanding how different components function, such as in a plush toy with voice recorder, illustrates the complexity added when integrating electronics or specialized fillings.

The Hardware: Functional Components

The hardware is what transforms a mini plush into a functional keychain. This seemingly minor detail has a significant impact on the product’s usability, durability, and perceived value. A low-quality clasp can undermine an otherwise excellent design.

Common hardware options include:

- Simple Metal Split Ring: The standard, cost-effective keyring. It is highly secure but can be difficult to attach or detach from other items.

- Lobster Clasp: A popular and practical upgrade. The spring-loaded mechanism allows for easy, one-handed operation, facilitating attachment to bags, zippers, or belt loops. It adds a touch of convenience and perceived quality.

- Ball Chain: Often used for smaller, lighter keychains. It is an economical choice but is the least durable option and not recommended for heavy daily use.

From the fabric’s texture to the solid click of a quality clasp, each component contributes to a final product that consumers will value and use.

The Factory Floor Production Workflow

Understanding how a design moves from a digital file to a physical product provides crucial insight for making informed decisions. The manufacturing process is a highly coordinated workflow, with each stage methodically executed.

The journey begins with a fundamental choice between two production models: OEM or ODM.

Original Equipment Manufacturer (OEM): This is for brands with a completely original design. You provide the technical specifications, artwork, and all unique details. We then act as your manufacturing partner to build the product from scratch. This is pure custom manufacturing.

Original Design Manufacturer (ODM): For brands seeking a faster market entry or a proven design foundation. You select a pre-existing design from our catalog, which we then customize with your logo, brand colors, or minor modifications. This is strategic adaptation.

Once the production model is determined, the factory operations begin.

From Digital Design to Physical Prototype

The first physical realization of your plush keychain is the prototype, or what we refer to as a “sample.” This is the most critical validation stage of the entire project.

Technical Design Review: Your artwork is submitted to our pattern masters, who analyze its complexity, construction, and manufacturability. They ensure the 2D design can be successfully translated into a 3D plush keychain.

Pattern Making and Cutting: A master pattern is created from your design. This blueprint is used to cut the fabric components with high precision, forming the outer “shell” of your keychain.

Prototyping (Sampling): Our most skilled artisans assemble the first unit by hand. This stage typically takes 5-10 business days and is where we refine seam allowances, embroidery placement, and overall construction. This physical sample is then shipped to you for approval.

We will not commence mass production until you have physically approved the sample. This step is your assurance that the final product will meet your exact specifications, eliminating any risk of unforeseen issues in the bulk order.

This diagram illustrates the core components that are assembled to create your keychain.

It shows how the outer shell, the soft filling, and the metal hardware are combined to create the finished piece.

The Mass Production Line

With the approved sample as our quality benchmark, we proceed to full-scale production. This involves multiple specialized teams working in a coordinated sequence.

First, all raw materials are procured in bulk—fabric, PP cotton, thread, and hardware. Following a rigorous quality inspection, these materials are moved to the production floor. The process then unfolds systematically. (For a comprehensive overview of the general workflow, our guide on how to make plush toys provides further detail.)

Decoration and Assembly

This is where the keychain’s character is defined, even before the pieces are sewn together.

Embroidery and Printing: The flat, cut fabric pieces are sent to the decoration department. Using computer-guided machines, we digitize your artwork to apply logos, facial features, and other details with high precision. For more complex graphics, silk-screen or heat-transfer printing methods are used.

Sewing and Assembly: Skilled sewing operators stitch the decorated pieces together, leaving a small, strategically placed opening for stuffing. This is a precision task, especially on complex shapes, to ensure clean, durable seams.

Stuffing and Finishing

The final stages involve bringing the keychain to its final, three-dimensional form.

The sewn shells are transferred to the stuffing station. Here, workers use specialized tools to fill each unit with a precise amount of PP cotton. The objective is to achieve a consistent density and feel across the entire production run—neither too firm nor too soft.

After stuffing, the opening is meticulously hand-stitched closed, creating a nearly invisible seam. Finally, the specified hardware—such as a split ring or lobster clasp—is securely attached. The finished keychain undergoes one last quality inspection before being packaged.

Understanding Costs and MOQs

The two most immediate questions from any B2B buyer are: “What is the unit cost?” and “What is your minimum order?” These are the foundational commercial parameters of any project. From the factory floor, these figures are not arbitrary; they are the output of a detailed manufacturing cost equation.

Understanding the inputs to this equation allows you to make strategic design choices that align with your budget. The final price of each plush toy keychain is a direct reflection of the materials, labor, and machine time invested at each stage.

What Drives the Unit Cost

The final price is influenced by several key factors. Adjusting these “levers” during the design phase is the most effective way to manage costs without compromising the product’s core appeal.

Design Complexity: A simple, spherical character with minimal seams is significantly faster to produce than a dragon with intricate wings, horns, and a detailed tail. A higher number of pattern pieces translates directly to increased cutting time, sewing labor, and assembly complexity, all of which drive up the cost.

Material and Filling Selection: As previously discussed, premium materials like long-pile faux fur are more expensive than standard crystal soft plush. Similarly, specialized fillings will increase the unit price over standard PP cotton.

Embroidery and Printing: The extent of decoration is a major cost factor. A design with dense, multi-color embroidery on both sides is more costly than one with a simple, single-color logo. We measure embroidery cost by stitch count—the higher the count, the higher the price.

Order Volume: This is the most direct pricing lever. Larger order quantities allow us to procure raw materials at lower bulk prices and optimize our production lines for maximum efficiency. Consequently, an order of 5,000 units will have a lower per-unit cost than a run of 500 units.

Why MOQs Are Essential

The Minimum Order Quantity (MOQ) often seems like a barrier for new brands. For a typical plush toy keychain, our MOQ ranges from 100 to 500 pieces. This threshold is not arbitrary; it is based on the economics of manufacturing.

The setup for each project involves significant preparatory work: pattern creation, embroidery machine programming, sourcing specific fabric dye lots, and configuring the assembly line. Amortizing these fixed setup costs over a very small order would result in an unviably high unit price. MOQs ensure that production is efficient, material waste is minimized, and we can offer you a commercially viable price.

For small items like plush keychains, China’s deeply integrated supply chain makes these low MOQs of 100–500 pieces feasible, with production turnarounds of 20–30 days while still meeting EN71 and ASTM safety standards. This unique manufacturing ecosystem is why China is the global leader for custom plush keychains supplied to international retailers, promotional campaigns, and licensed merchandise programs. To better understand this landscape, you can learn about China’s top toy manufacturers.

Practical Tips for Reducing Costs

Achieving your target cost does not require sacrificing quality. Strategic adjustments during the design phase can significantly impact the final unit price.

The most effective cost-saving measures are implemented during the initial design phase. A minor modification to a digital file can lead to substantial savings during mass production. Attempting to make changes after sample approval is significantly more costly.

Here are several actionable strategies:

- Simplify the Design: Reduce the number of separate fabric pieces. Fewer seams mean faster assembly and lower labor costs.

- Optimize Decoration: Consider the size and color count of your embroidery. A slightly smaller logo can dramatically reduce the stitch count and machine time.

- Choose Standard Materials: Utilizing our in-stock fabrics and colors eliminates custom dyeing fees and the minimum order requirements associated with special-order materials. For businesses scaling up, exploring plush toys wholesale provides cost advantages on standard designs.

- Increase Order Quantity: If feasible, increasing your order volume is the most direct way to reduce the per-unit cost due to economies of scale.

Meeting Global Quality and Safety Standards

In toy manufacturing, safety is not a feature; it is the absolute foundation of the entire process. For any brand, a single safety failure can lead to product recalls, legal liability, and irreparable damage to consumer trust.

For this reason, our quality control (QC) is not a final inspection but a multi-stage system integrated throughout production. We embed quality assurance checkpoints at every step, from raw material arrival to final packaging. This methodology protects not only the end-user but also your brand and your investment.

Our Multi-Stage QC Inspection Process

Early detection of issues is paramount. A robust QC process establishes inspection points at critical manufacturing stages to identify potential defects before they are replicated across a large batch. This approach saves time, reduces material waste, and prevents minor errors from escalating into major production problems.

Our inspection process is divided into three key phases:

- Raw Material Inspection (IQC): Before any material enters the production line, our team conducts a thorough inspection. We verify fabric colors against Pantone standards, ensure PP cotton is clean and hypoallergenic, and test keychain hardware for strength and durability.

- In-Process Inspection (IPQC): During production, our quality inspectors are on the factory floor, monitoring key processes. They check embroidery stitch density, seam strength, and the consistency of stuffing across units.

- Final Product Inspection (FQC): Once a keychain is fully assembled, it undergoes a final, comprehensive inspection. Every unit is examined for visual defects, structural integrity, and, most importantly, safety compliance.

A critical component of the FQC is the needle detection process. Every single plush keychain must pass through a calibrated metal detector. This is a non-negotiable step to ensure no broken needle tips or other metal fragments have been inadvertently left inside the product during sewing. It is a vital safeguard for consumer safety.

Navigating International Safety Standards

To sell your plush keychains in international markets, you must comply with their mandatory safety regulations. The two most important standards for B2B buyers to know are EN71 for the European Union and ASTM F963 for the United States.

A manufacturer’s ability to consistently produce compliant products is a clear indicator of their experience and reliability. We ensure that our materials and production methods adhere to these strict chemical and physical safety requirements from the project’s inception.

Key Safety Standards for Plush Toys

This table provides a summary of what these essential standards regulate. Understanding these is crucial for ensuring your product is market-ready.

| Standard | Governing Region | Key Focus Areas |

|---|---|---|

| EN71 | European Union | Covers mechanical and physical properties (e.g., small parts, sharp edges), flammability, and the migration of certain chemical elements like lead and mercury. |

| ASTM F963 | United States | Regulates mechanical hazards, flammability, lead content, and other toxic substances. It is a mandatory consumer product safety standard for all toys sold in the US. |

Choosing a manufacturer is an act of entrusting them with your brand’s reputation. Partnering with a factory that has a documented QC system and a deep understanding of global compliance is not just about buying a product—it is about securing your brand’s integrity.

Choosing the Right Manufacturing Partner

Selecting the right factory is the single most critical decision in your plush toy keychain project. A strong partner acts as an extension of your team, providing not just production capacity but also valuable industry expertise. Conversely, a poor choice can lead to costly delays, substandard quality, and significant risk to your brand’s reputation.

A successful partnership is built on two pillars: proven experience and transparent communication. When vetting potential factories, look beyond the unit price. Investigate their production history. A client list that includes major IP holders like Sanrio or Starbucks is a strong indicator of their ability to meet demanding quality standards and manage complex projects.

Key Qualities of a Reliable Partner

Communication is equally vital. A reliable partner responds to inquiries promptly, provides realistic timelines, and proactively informs you of potential challenges. If you find yourself chasing a factory for basic information during the quoting process, it is a clear red flag for how communication will be once production begins.

Look for these key attributes:

- End-to-End Service: A factory that manages the entire process—from design optimization and prototyping to mass production and logistics—simplifies your operations immensely.

- Flexible MOQs: While all factories have minimums, a partner willing to discuss orders in the 100–500 piece range understands that businesses need a viable starting point.

- Deep Market Knowledge: An experienced manufacturer possesses valuable market insights. They understand, for example, that the Chinese domestic market favors small, collectible, and customizable items, making keychains an ideal entry-level product. This expertise can be invaluable during product development. You can learn more about China’s toy market forecast to see these trends in action.

Why FunEnjoy Is a Trusted Manufacturer

With over 30 years of manufacturing experience, we at FunEnjoy have built our reputation on reliability and quality. We do not just process orders; we build long-term partnerships. Our process is designed to be comprehensive and transparent, providing you with complete confidence from initial concept to final delivery.

Your success is our success. A high-quality product that delights your customers and strengthens your brand is the ultimate goal of our collaboration. We are committed to turning your vision into a tangible, high-quality plush toy keychain.

If you are seeking a dependable partner to manufacture your next plush keychain, our team is ready to provide expert guidance. We invite you to share your project details with us and discover how our experience can ensure a smooth and successful production run.

Your Manufacturing Questions, Answered

If you are new to custom plush keychain production, you likely have many questions. These are common inquiries we receive from clients, and we have provided clear, factory-direct answers to help you navigate the process.

What Is the Typical Timeline from Sample to Shipment?

A typical project timeline proceeds in two main phases. First, after receiving your complete design specifications, we create a physical sample. This process usually takes 5-10 days. This step is crucial for design verification.

Once you have approved the physical sample, we commence mass production. For a standard order, the production phase takes approximately 20-30 days. Highly complex designs or very large quantities may affect this timeline, but we will always provide a detailed production schedule with your official quotation.

How Do You Ensure the Final Product Matches My Brand Colours?

Precise color matching is critical. We use the Pantone (PMS) color matching system for all fabrics and embroidery threads. This is the global industry standard and eliminates subjectivity in color specification.

Before mass production begins, you will receive a physical prototype made with the specified materials and colors. We consider this the “master sample.” We will not proceed with the bulk order until you are 100% satisfied with this sample, giving you full control over the final product’s appearance.

What Kind of Artwork Files Do You Need to Start a Project?

For optimal results, vector files are strongly preferred. Formats such as Adobe Illustrator (.AI) or .EPS allow our pattern makers to scale your design perfectly without any loss of detail.

If vector files are unavailable, high-resolution PDFs or JPEGs can be used, provided they clearly show all angles, colors, and dimensions. The ideal submission is an industry-standard “tech pack,” which is a detailed document outlining all specifications, from material types to stitching methods.

Do You Handle International Shipping and Logistics?

Yes, we manage the entire logistics process. With decades of export experience, we handle shipping from our factory in China to your designated warehouse or port anywhere in the world.

We can arrange shipping to meet your specific timeline and budget requirements. The primary options are:

- Sea Freight: The most cost-effective option for larger orders where transit time is less critical.

- Air Freight: A faster but more expensive option, suitable for urgent orders or smaller, high-value shipments.

We provide quotes based on various shipping incoterms (e.g., FOB, CIF, DDP) to ensure the delivery process is clear and predictable for your business.

Ready to transform your plush keychain concept into a high-quality product with a reliable manufacturing partner? The team at FunEnjoy PlushToys is here to guide you through every step. Contact us today to discuss your project and get a quote.