As a plush manufacturer based in China, we are the operational partner that transforms a creative concept into a tangible, high-quality stuffed toy. This is not simply a matter of sewing fabric. It is a comprehensive process encompassing design refinement, material sourcing, prototyping, mass production, rigorous safety testing, and global logistics. Our role is to bridge the gap between your vision and a market-ready product.

Why China Remains the Global Hub for Plush Manufacturing

For decades, international brands have relied on China’s manufacturing capabilities, not solely for cost advantages, but to access a mature, integrated ecosystem built on specialized skill and supply chain efficiency. China is the undisputed global center for toy production, a status earned through generations of craftsmanship and a deeply interconnected network of suppliers.

Within our manufacturing region, we have immediate access to a vast array of resources—from premium fabrics like custom-milled minky to specialized embroidery threads and certified recycled fillings. This proximity is a significant operational advantage.

This condensed supply chain allows an experienced plush manufacturer to operate with exceptional speed and precision. We can procure unique materials on short notice, solve complex engineering challenges in a design, and scale production rapidly without compromising quality. This level of agility is difficult to replicate elsewhere. The industry here is a finely-tuned machine, structured to meet the stringent quality and safety regulations of international markets like the EU and the US.

The Scale of the Plush Toy Market

The global demand for plush toys continues to expand, driven by entertainment franchises, corporate branding, and the growing market for collectibles. The toy market in China, a significant portion of which is plush manufacturing, is projected to reach $78.21 billion by 2027. This growth is fueled by our position as the primary export engine, supplying approximately 85% of all toys sold in the United States.

As manufacturers on the factory floor, we observe these trends firsthand. The demand is not just for higher volume, but for greater sophistication. We see a significant increase in requests for unique textures, sustainable materials like recycled PET filling, and intricate character details that require advanced production techniques.

This dynamic market compels us to continuously refine our methods and stay ahead of industry trends. To understand how these market shifts influence product development, see our analysis on the latest trends in plush toy design. Partnering with the right manufacturer is not just about production; it’s about accessing a deep reservoir of industry knowledge to create a product that resonates with consumers.

The Manufacturing Process: From Sketch to Stuffed Toy

Transforming a 2D drawing into a 3D plush toy is a meticulous process that combines technical skill with artistry. Our function is to ensure every aspect of a character’s personality is accurately translated into fabric and thread. This is a workflow we have perfected over decades, beginning with your design concept.

You provide the initial idea—whether it’s a simple sketch or a detailed technical package with Pantone color specifications. We then convert that creative spark into a viable manufacturing blueprint.

From 2D Concept to 3D Pattern

The first critical step on the factory floor is pattern-making. Our master pattern makers analyze your design’s every curve, dimension, and unique feature. They then deconstruct the character into a series of individual fabric components, creating a precise paper or digital pattern for each part—ears, limbs, torso, and so on.

This is analogous to a tailor creating a bespoke suit; each piece must fit together perfectly to achieve the intended form. This stage is paramount, requiring a deep understanding of how different fabrics stretch and behave when sewn. A flawed pattern is a primary cause of production defects, resulting in misshapen or inconsistent toys.

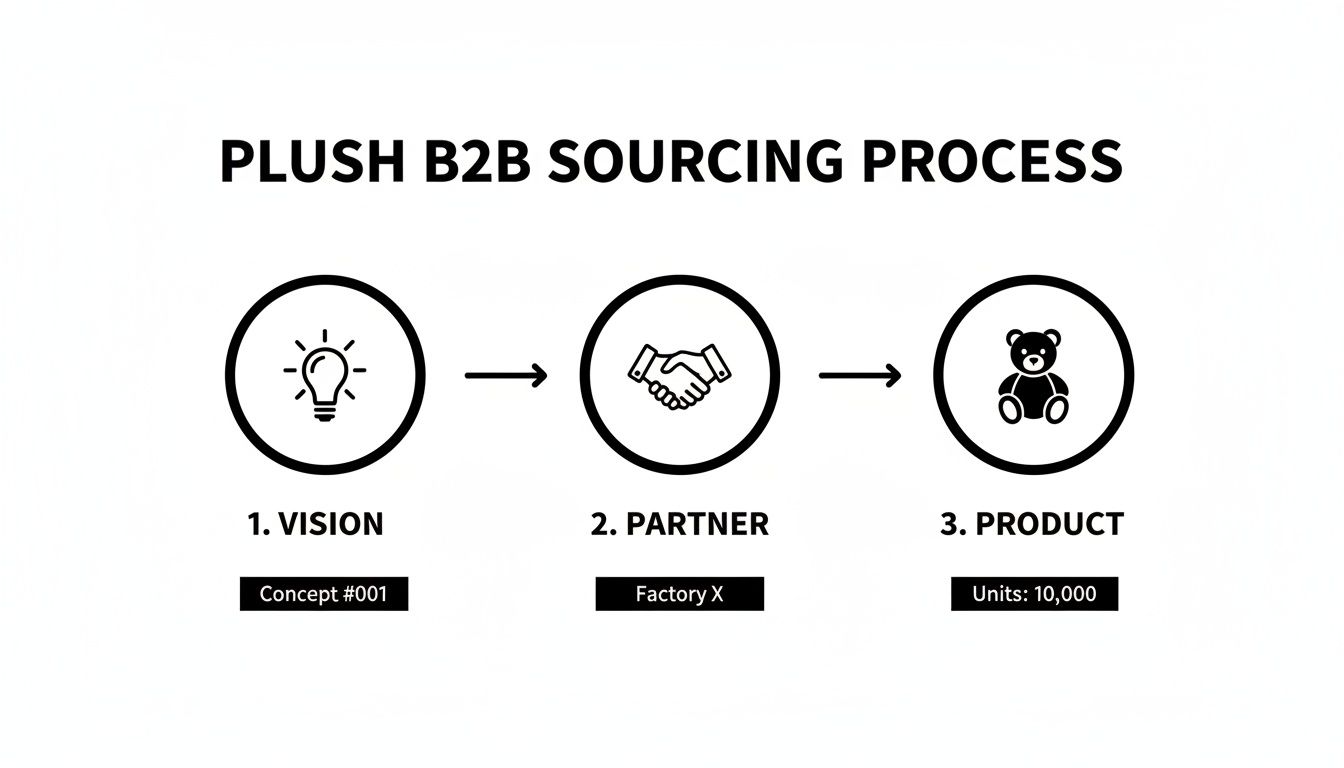

This process diagram provides a high-level overview of the entire journey, from your initial vision to selecting a partner and receiving your finished product.

A successful project depends equally on a clear creative vision and a capable manufacturing partner.

Once the pattern is finalized, we proceed to material selection and cutting. Whether you have specified ultra-soft minky, classic velboa, or a custom-printed fabric, we cut each piece with exacting precision using the master patterns. For large-scale orders, laser cutters are employed to ensure absolute uniformity across thousands of units. This is non-negotiable for maintaining consistency.

Assembly, Embroidery, and Stuffing

With the fabric pieces cut, the assembly line begins its work. This is where the character starts to take physical shape.

First, embroidery and other detailed features like appliqués are applied while the fabric pieces are still flat. Computer-guided machines stitch eyes, mouths, and logos, ensuring perfect replication and consistency. It is far more precise and efficient to embroider on flat panels before they are sewn together.

Next, our skilled sewing teams assemble the individual pieces in stages, transforming a collection of flat shapes into a hollow plush “skin.” This requires significant expertise, particularly for complex designs with numerous small components.

A critical, often-overlooked step is achieving the correct stuffing density. Insufficient stuffing results in a limp, low-quality feel; excessive stuffing makes the toy hard and less huggable. Our technicians use calibrated blowing machines to fill each plush with a precise volume of PP cotton or other specified filling to achieve the desired tactile feel and weight.

After stuffing, the final opening is closed with a concealed ladder stitch, and the toy undergoes final shaping. Our team manually adjusts the stuffing and grooms the features of every plush to ensure it perfectly matches the approved prototype. This hands-on finishing is what imparts the final personality to the character. Understanding these steps is crucial if you plan to design your own plush toy with a manufacturer.

The Critical Prototype Stage

Before mass production commences, we create a prototype. We refer to this as the “golden sample” because it is the single most important checkpoint in the entire manufacturing process.

- Initial Sample Creation: We build the first physical version of your toy based on your designs. The typical timeline for a first sample is 5-10 business days.

- Client Feedback: We ship this sample to you for physical evaluation. This is your opportunity to assess the materials, construction, and overall accuracy.

- Revisions: Based on your feedback, we adjust the pattern, materials, or embroidery and create a revised sample.

- Final Approval: Mass production does not begin until we receive your final, written approval of the golden sample. This sample then becomes the definitive quality standard that every unit in the production run must meet.

This iterative process eliminates ambiguity and ensures the final product aligns exactly with your expectations.

Choosing Your Path: OEM vs. ODM Manufacturing

When engaging with a plush manufacturer, you will encounter two primary business models: OEM and ODM. Understanding the distinction is a critical early decision that will influence your project’s timeline, budget, and the uniqueness of your final product.

The choice depends on your business objectives, whether you have a pre-existing design, and your desired speed to market.

Consider the analogy of building a house. OEM is akin to commissioning a custom-built home where you provide the architectural blueprints. ODM is like selecting a model home from a developer’s portfolio and customizing the finishes.

The Custom Build: OEM Model

Original Equipment Manufacturing (OEM) is the appropriate model when you have a unique, proprietary design that you need produced. You provide us with a complete technical package—detailed drawings, fabric specifications, Pantone color codes, and precise dimensions. As the manufacturer, our role is to execute your blueprint with precision.

Under this model, you retain 100% creative control and full intellectual property rights. Your design is exclusive to you.

- Best For: Brands launching a signature character, companies with licensed IP (e.g., from film or gaming), or organizations requiring a bespoke corporate mascot.

- Process: This is an intensive, collaborative process involving a detailed prototyping phase, often with several rounds of revisions, to ensure the final product perfectly matches your vision before mass production.

- Outcome: A one-of-a-kind product that cannot be replicated by competitors.

For example, a major film studio would use the OEM model to produce merchandise for a new animated character, ensuring every plush toy is a perfect and consistent representation of their on-screen IP.

The Fast Track: ODM Model

Original Design Manufacturing (ODM) is the optimal choice if you aim to launch a high-quality product quickly without investing in design from scratch. As an established manufacturer, we maintain a portfolio of pre-developed, market-tested plush designs. You select a base model from our catalog, which we then customize for your brand.

Customization can include adding your logo via embroidery or a woven label, changing fabric colors to align with your brand identity, or designing unique packaging. It is a significantly faster and more cost-effective path to market.

With ODM, you are leveraging our design expertise and production-ready patterns. This drastically reduces the development time and costs associated with creating a new design from the ground up.

- Best For: Retailers needing seasonal products (e.g., Valentine’s Day bears), companies executing promotional campaigns with tight deadlines, or startups looking to test a product category.

- Process: Much faster. You select a design, we produce a sample with your branding, and upon approval, we can proceed directly to mass production.

- Outcome: A high-quality, customized product that can be launched in a fraction of the time required for an OEM project.

A boutique gift shop, for example, could use our ODM service to create a line of teddy bears in its signature corporate colors for the holiday season, securing a proven seller without the long lead time of a custom design.

Decoding the Costs of Custom Plush Toys

A primary question from clients is, “What is the unit cost?” There is no single answer, as the final price of a custom plush toy is determined by a series of specific decisions regarding its design, materials, and production volume. Our role is to provide transparency on these cost drivers, enabling you to make informed decisions that align with your budget without compromising quality.

Understanding these factors allows you to see precisely how your budget is allocated and helps us collaborate on cost-engineering solutions, such as minor design modifications that can reduce cost without altering the aesthetic intent.

Material Choices and Their Price Impact

The fabrics and fillings selected are the foundation of your toy’s cost and perceived value.

Fabric Type: Standard materials like velboa or fleece are cost-effective and suitable for a wide range of applications. For a premium, softer feel, fabrics such as minky are preferred. Custom-printed fabrics, which require a separate manufacturing process, also increase the unit cost due to higher raw material and setup expenses.

Filling Material: The industry standard is polypropylene (PP) cotton, which offers an excellent balance of softness, resilience, and affordability. For brands with a sustainability focus, we offer eco-friendly options like recycled PET filling (made from post-consumer plastic bottles). This option typically carries a 15-20% cost premium over standard PP cotton.

The quantity of filling also impacts cost. A densely packed, firm toy requires more material than a softly filled one, which is reflected in the final price.

How Design Complexity Affects Labour Costs

The complexity of a plush toy’s design directly correlates to the amount of skilled labor required for its assembly, which is a major cost component.

A simple, spherical character is significantly faster—and therefore less expensive—to produce than a detailed character with multiple limbs, accessories, and extensive embroidery. Every additional component, such as a separate hat, a jacket, or individually stitched fingers, adds more steps to the assembly process. Each part must be cut, sewn, and attached by hand.

A key cost driver is the number of individual pattern pieces required. A basic ball shape might only need six pattern pieces. A complex dragon with wings, horns, and a segmented tail could easily require over thirty, which translates directly to increased sewing time per unit.

For this reason, design simplification is often the most effective method of cost reduction. For example, replacing two small, sewn-on felt pieces with a single, elegant embroidered detail can significantly reduce labor time and cost.

The Role of Size and Order Quantity

The physical size of the toy and the total volume of your order are two fundamental pricing factors. A larger toy requires more fabric and filling and occupies more volume during shipping. A 20cm plush will invariably cost less to produce and ship than an otherwise identical 40cm version.

Equally important is the total order quantity, which allows for economies of scale.

Setup Costs: Every production run involves fixed setup costs, from creating cutting dies to programming embroidery machines. When these one-time costs are amortized over a large order of 5,000 units versus a small order of 500 units, the cost-per-unit decreases substantially.

Material Sourcing: We secure more favorable pricing from our suppliers when purchasing fabric and filling in bulk for a large production run. These savings are passed directly to you.

The unit price for a 10,000-piece order will be considerably lower than for a 1,000-piece order of the same toy.

Factoring in Safety and Certification

Safety testing is not an optional expense; it is a mandatory investment that protects your brand and your customers. We ensure every product complies with stringent international safety standards such as EN71 (for Europe) and ASTM F963 (for the USA). The cost for third-party laboratory testing is typically factored into the overall project budget.

This is one of the most critical investments you will make. Partnering with a manufacturer that prioritizes safety protects you from the significant financial and reputational risks of a product recall and ensures your toy is safe for all end-users.

MOQs, Quality Control, and Safety Standards Explained

Beyond design and costing, three operational pillars define a successful production run: Minimum Order Quantities (MOQs), quality control, and safety compliance. These are not mere line items on a quotation; they are the foundational elements of reliable manufacturing. Understanding these from a manufacturer’s perspective is key to a smooth partnership and a successful product launch.

We view these three elements as interconnected. A reasonable MOQ allows for efficient material sourcing, which is the first step in quality control. A robust quality process then ensures every unit produced can pass rigorous international safety testing.

Understanding Minimum Order Quantities (MOQs)

The MOQ is not an arbitrary number; it is a reflection of the supply chain’s operational realities. Fabric mills, dye houses, and thread suppliers all have their own minimum production quantities that we must adhere to.

Our MOQ enables us to purchase raw materials in bulk, securing fair pricing and allowing for efficient, continuous production runs. Without MOQs, the per-unit cost would increase dramatically due to small-batch material purchasing and constant machine setup and teardown.

For most custom designs, our factory’s typical MOQ ranges from 100 to 500 pieces. This flexibility is a direct result of our location and scale. China’s plush toy industry accounts for nearly 70% of global production, with exports exceeding $54 billion. This immense scale allows established factories like ours to offer competitive MOQs and rapid 20–30 day production lead times, all while maintaining strict compliance with EN71 and ASTM standards. This is the reliability that global brands depend on.

Our Multi-Stage Quality Control (QC) Process

Quality control is not a final inspection; it is a continuous process integrated into every stage of production. The objective is to identify and rectify potential issues early, preventing systemic problems, reducing waste, and ensuring every toy is a perfect replica of the approved “golden sample.”

Our QC system includes several key checkpoints:

- Incoming Materials Inspection (IQC): Before any raw materials enter the production floor, our QC team inspects them for defects, color accuracy, and compliance with specifications. Identifying a flaw in a roll of fabric at this stage prevents the production of hundreds of faulty units.

- In-Process Quality Control (IPQC): As the plush toys move through cutting, embroidery, and sewing, line supervisors conduct random inspections. They check stitch tension, embroidery clarity, and assembly accuracy against the approved standard.

- Final Quality Control (FQC): Once a toy is fully assembled and stuffed, 100% of the units undergo a final manual inspection. Our team checks for symmetry, stuffing consistency, seam strength, and overall appearance against the golden sample. This stage also includes passing every toy through a metal detector to ensure no foreign objects (like a broken needle tip) are present.

This layered methodology is the only way to guarantee consistency across a production run of thousands of pieces. It is a fundamental part of our commitment, whether we are producing a corporate mascot or a custom stuffed animal of your pet.

Safety Standards: A Non-Negotiable Requirement

For any brand selling toys, safety is paramount. Adherence to international safety standards is a legal requirement that protects your business and, most importantly, the end-user. The two predominant standards for our clients are EN71 for the European Union and ASTM F963 for the United States.

Partnering with a manufacturer who has deep expertise in these standards is critical. They are not just certificates; they dictate material selection, construction methods, and labeling requirements.

The testing is comprehensive and covers three primary areas:

- Mechanical and Physical Properties: This ensures the toy can withstand pulling, twisting, and dropping without small parts detaching and creating a choking hazard. Seam strength and the secure attachment of components like plastic eyes are tested rigorously.

- Flammability: Fabrics and fillings must meet strict fire-resistance criteria to ensure the toy will not easily ignite or burn rapidly if exposed to a flame.

- Chemical Testing: This is a highly complex area where laboratories test for the presence and migration of harmful substances like lead, mercury, and specific phthalates. We exclusively source materials from suppliers who can provide certification that their dyes and fabrics are free of these banned substances.

A failure in any of these tests can result in a shipment being seized at customs, a product recall, and severe damage to a brand’s reputation. We design for safety from the initial concept stage.

Global Safety Standards Compared: EN71 vs. ASTM F963

This table provides a concise comparison of the two leading safety standards we manage daily. While their goal is the same—child safety—their technical requirements and areas of focus differ.

| Safety Aspect | EN71 (European Union) | ASTM F963 (United States) |

|---|---|---|

| Mechanical/Physical | Focuses heavily on risks like choking, strangulation, and suffocation. Specifies tests for seams, small parts, and sharp edges. | Also covers small parts and structural integrity. Includes drop tests and torque/tension tests for components like eyes and noses. |

| Flammability | Has specific “rate of spread of flame” tests to ensure materials don’t ignite and burn too quickly. | Requires materials to be self-extinguishing after being exposed to a flame. The test methods and requirements differ slightly. |

| Chemical Safety | Regulated by the REACH directive. Restricts a long list of chemicals and heavy metals, testing for their “migration” from the toy. | Governed by the CPSIA. Sets strict limits for lead and phthalates. All children’s products must be third-party tested. |

| Labelling | Requires the “CE” mark, manufacturer’s details, and specific warnings (e.g., “Not suitable for children under 36 months”). | Requires a permanent tracking label on the product, including manufacturer name, production date, and batch number. |

Navigating these regulations is our responsibility, but a basic understanding helps you appreciate why certain design and material choices are recommended. We engineer every toy for compliance from the outset, ensuring a safe product and seamless market entry.

Finding Your Perfect Plush Manufacturing Partner

Selecting a plush manufacturer is the most critical decision in your product development journey. This should be viewed not as a transactional purchase but as a long-term strategic partnership. A competent manufacturer acts as an extension of your team, providing the technical expertise to translate your concept into a safe, high-quality, and commercially viable product. The right partner will not just follow instructions; they will offer guidance, anticipate problems, and ultimately safeguard your brand’s reputation.

Conversely, a poor choice can lead to a cascade of issues, including missed deadlines, inconsistent quality, and critical safety compliance failures that can jeopardize your business. One of the most common mistakes we see is brands selecting a factory based solely on the lowest price—a decision that frequently incurs far greater costs in the long term.

What a True Manufacturing Partnership Looks Like

A strong manufacturing relationship is founded on trust, transparency, and a proven track record. It’s not just about a factory’s machinery, but about their experience and communication protocols.

Key attributes of a reliable partner include:

- Deep Experience: A long operational history, like our own dating back to 1993, indicates that a factory has navigated a wide range of production challenges and has robust processes in place.

- End-to-End Capabilities: The best partners manage the entire process in-house, from design optimization and prototyping to mass production and logistics coordination. This streamlines the process for you.

- Transparent Communication: You require a partner who provides clear, honest, and timely updates. Proactive communication is a hallmark of a professional operation.

The plush manufacturing industry in China is more globally connected than ever. With the plush toy sector forecast to grow from USD 15.6 billion to USD 21 billion by 2034, leading factories leverage technology for transparent project management and rapid communication. This is no longer a bonus; it is a fundamental requirement. You can explore a detailed China’s toy market forecast.

Why Brands Trust FunEnjoy

We operate as production partners, not just a factory. With decades of experience manufacturing for global brands like Sanrio and The North Face, our business is built on three pillars: uncompromising quality, operational transparency, and a commitment to partnership.

Our all-in-one service model means we manage the technical complexities, allowing you to focus on your brand. We provide flexible MOQs, deliver quotations within 24 hours, and assign a dedicated project manager to guide you through every step. Bring us your next project, and let us demonstrate the standard of service you should expect from a world-class plush manufacturer.

Answering Your Top Questions

After decades in this industry, we’ve found that the same key questions arise with nearly every new partner. Here are direct, practical answers from the factory perspective to provide clarity and help you avoid common pitfalls.

What Is a Realistic Timeline for a Custom Plush Toy Order?

A reliable timeframe for a standard custom project is approximately 6 to 8 weeks from final design approval to cargo arrival at your destination port. This is a realistic schedule to base your product launch planning around.

Here is a typical breakdown of that timeline:

- Design & Prototyping: This initial phase takes 5-10 business days. This includes the creation of the first physical “golden sample” and allows for one or two rounds of revisions based on your feedback.

- Mass Production: Upon your approval of the golden sample, full production typically takes 20-30 days. The exact duration depends on the complexity of your design and the total order quantity.

- Shipping: Ocean freight transit is the final stage. This generally requires an additional 2-4 weeks to reach major ports in North America or Europe.

We provide a detailed production and shipping schedule at the start of every project, ensuring you have full visibility at all times.

How Do I Ensure the Final Product Matches My Design?

The prototype, or “golden sample,” is the mechanism that guarantees this. It is the single most important quality assurance checkpoint in the entire process. We translate your 2D designs into a physical sample that you can hold and evaluate.

We ship this sample to you for thorough inspection. This is your opportunity to assess the fabric feel, stitch quality, stuffing density, and overall fidelity to your original concept.

We adhere to a strict and simple rule: mass production never commences until you are 100% satisfied with the golden sample and provide written sign-off. That approved sample then serves as the control standard. Every unit that comes off the production line is compared against it to ensure absolute consistency.

What Are Common Mistakes to Avoid When Sourcing Plush Toys?

Based on our experience, several common but avoidable errors can derail a project. From our perspective as manufacturers, these are the three most significant pitfalls for new brands.

- Overly Complex Designs for the Price Point: While intricate designs are appealing, they may be impractical to produce consistently at a target cost. Designs with numerous tiny, separate parts often lead to higher defect rates and increased labor costs. Often, simplifying a few minor elements can dramatically improve production quality and cost-effectiveness without sacrificing the character’s appeal.

- Overlooking Safety Testing Logistics: Failing to budget for and schedule third-party safety testing (e.g., EN71, ASTM F963) is a critical error. A failed test can result in an entire shipment being rejected at customs, leading to significant financial loss and logistical nightmares.

- Choosing a Supplier Based on Price Alone: This is the highest-risk decision you can make. An unusually low quotation often indicates that corners are being cut, whether in material quality, ethical labor practices, or quality control. A reliable manufacturer provides a fair price that reflects their expertise, quality systems, and commitment to a successful outcome.

At FunEnjoy PlushToys, our goal is to build long-term partnerships, not just fulfill orders. Our team is prepared to guide you through the entire manufacturing process, ensuring your vision is realized as a high-quality, safe, and successful plush toy. Contact us today to talk about your project and get a quote within 24 hours.