A custom pet plush isn’t just another promotional item; it’s a physical representation of your brand, character, or intellectual property. From our position as a plush toy factory in China, we see many brands stumble during the sourcing process. The most common mistake? Underestimating the technical knowledge required to move from a 2D sketch to a shipping container of finished, compliant products. This guide provides the practical, manufacturer-level insights needed to navigate the process successfully.

Market Overview: A Factory-Floor View of the Plush Toy Industry

Bringing a custom plush to life is far more complex than simply sewing fabric. The process involves translating a 2D design into a precise 3D pattern, sourcing materials with batch-to-batch consistency, and navigating a complex web of international safety standards. A misstep in any of these areas can lead to costly delays, budget overruns, or a final product that fails to meet market expectations.

From our factory in Yiwu, we have a direct view of the global demand for plush toys. China has long been the manufacturing hub for this industry. In 2024, China’s domestic market for stuffed and plush toys reached US$1.1 billion, with projections to double to US$2.2 billion by 2034. This is driven by a massive export industry, which accounted for 58% of the entire worldwide share of toy exports in 2022. For a deeper analysis, you can review the full research on plush toy market trends.

Why Brands Choose Custom Plush Toys

A custom plush offers unique benefits that other merchandise cannot:

- Tangible Brand Connection: It creates a physical, emotional bond with your audience.

- High Perceived Value: A well-made plush is seen as a premium product, not a disposable giveaway.

- Marketing Versatility: It serves as a retail product, a promotional tool, or a corporate mascot.

This guide provides a transparent, manufacturer’s perspective on the entire production journey. We will cover the technical details of the manufacturing process, pricing, quality control, and logistics to equip you with the knowledge needed for a successful launch.

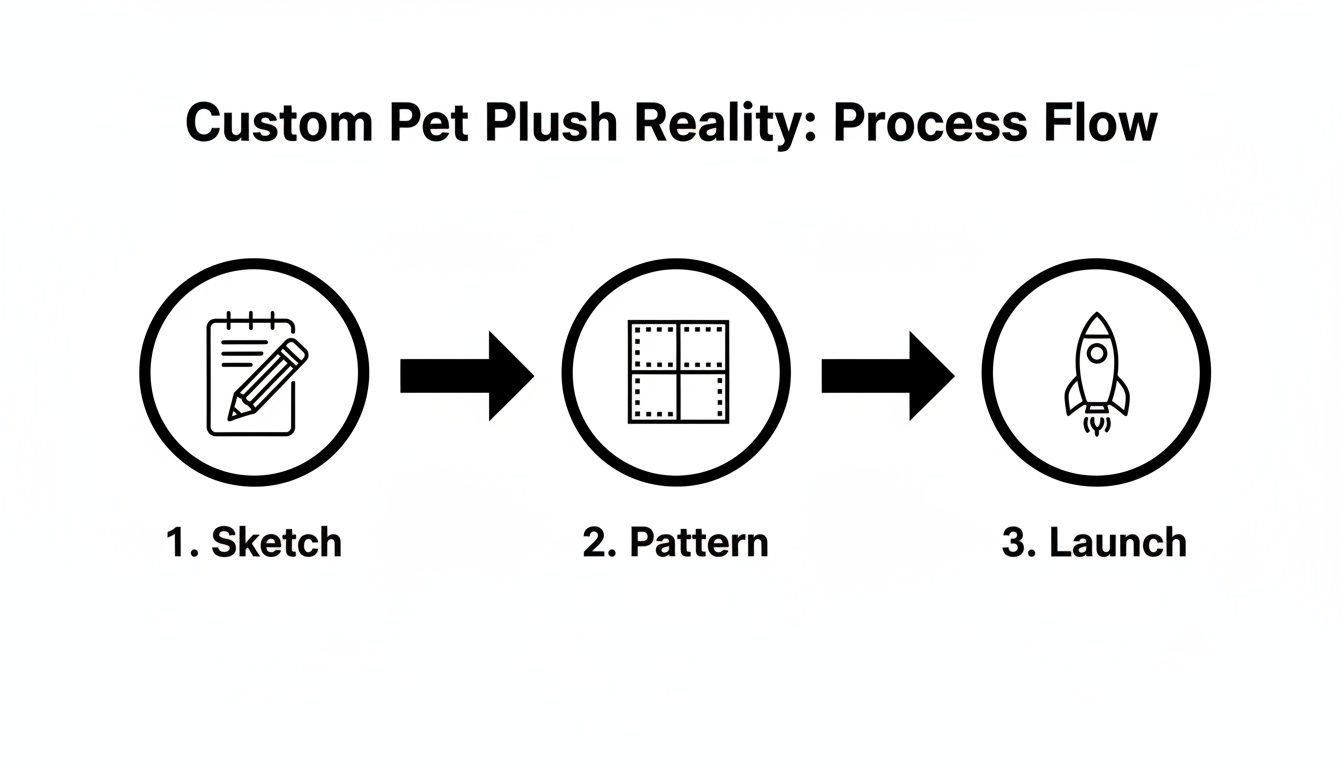

The Manufacturing Process: From Design to Finished Product

The journey from concept to mass production is a structured process that relies on clear communication and technical precision. Understanding each stage is critical for any brand looking to source plush toys directly from a factory.

Step 1: Prototyping and Sampling

This is where your design is translated into a physical object. The success of this stage depends entirely on the quality of your technical design file, or “tech pack.” A detailed tech pack provides the blueprint for our pattern makers, specifying everything from Pantone color codes to stitch types.

Prototyping Workflow:

- Pattern Making: Our master pattern makers deconstruct your 2D artwork into a series of fabric pieces that will form the 3D shape.

- Material Cutting: Fabric is cut using either die-cutting for high-volume, simple shapes or laser cutting for complex, detailed designs.

- Embroidery & Printing: Details like eyes, logos, or markings are applied to the flat fabric pieces before assembly for maximum precision.

- Sample Assembly: Our most skilled sewing technicians hand-assemble the sample, stuff it with the specified filling, and perform an initial quality check against your tech pack.

The first prototype is a physical draft—our best technical interpretation of your design. It serves as the tangible starting point for your feedback and any necessary revisions.

Sampling Timeline:

Typically, creating and shipping the first prototype takes 5 to 10 working days. This can be influenced by:

- Material Sourcing: Custom-dyed fabrics or unique materials require additional sourcing time.

- Design Complexity: Intricate designs with many components take longer to pattern and assemble.

- Client Feedback: The speed of revisions depends on the clarity and specificity of your feedback.

A comprehensive design brief is the most effective way to reduce the sampling timeline and associated costs. For more guidance, learn more about how to design your own plush toy.

Step 2: Material and Filling Selection

The materials you choose define the final product’s look, feel, safety, and cost.

Common Fabric Types:

- Crystal Velboa: A short-pile, smooth fabric ideal for vibrant, detailed printing. It is the industry standard for cost-effective, high-quality plush.

- Minky Fabric: Known for its ultra-soft, plush feel. It has a slightly longer pile and is often associated with premium baby products.

- Faux Fur (Sherpa/Long-Pile): Essential for replicating fluffy or shaggy coats. The cost varies based on fiber length and density, and it requires more skilled labor to work with.

Common Filling Types:

- 100% Virgin PP Cotton: The industry standard. We use high-elasticity, hypoallergenic polyester fiber fill to ensure the plush maintains its shape.

- Recycled Polyester (rPET): An eco-friendly option made from recycled plastics, offering similar performance to virgin polyester.

- Plastic or Glass Beads: Used to add weight and stability, typically sealed in a secure inner pouch in the base or paws to help the plush sit upright.

Step 3: Mass Production

Once the pre-production sample is approved, mass production begins. For an order of 500 to 5,000 units, the typical production timeline is 20 to 30 days.

Mass Production Workflow:

- Bulk Material Sourcing (5-7 days): Ordering all required fabrics, fillings, and accessories.

- Cutting & Embroidery (3-5 days): All fabric panels are cut, and embroidery is completed.

- Sewing & Assembly (10-15 days): The main production line phase where toys are sewn, stuffed, and finished.

- Final QC & Packing (2-3 days): Each unit undergoes final inspection, cleaning, and packing.

Pricing Factors: What Impacts Your Unit Cost?

A transparent manufacturer can break down exactly what contributes to your final unit cost.

- Material Consumption: Larger toys and premium fabrics (like faux fur) increase cost.

- Design Complexity: The number of pattern pieces and sewing operations directly impacts labor time. A simple sphere is far less costly to produce than a character with detailed clothing.

- Labor and Assembly: Additional features like clothing, accessories, or weighted pouches require extra manufacturing steps, increasing labor costs.

- Compliance and Testing: The cost of third-party safety testing is often factored into the project, while our internal QC processes also represent an operational cost.

Factory Tip: To reduce cost without compromising quality, focus on design simplification. Reducing the number of fabric colors, simplifying embroidery, or slightly decreasing the overall size can yield significant savings.

OEM vs. ODM: Understanding Your Production Model

- OEM (Original Equipment Manufacturer): This is the model for a fully custom pet plush. You provide a unique design, and we manufacture it to your exact specifications. You retain all intellectual property.

- ODM (Original Design Manufacturer): In this model, you select a pre-existing design from our catalog and customize it (e.g., changing colors, adding a logo). This is faster but offers less originality.

Minimum Order Quantity (MOQ) Explained

Our standard Minimum Order Quantity (MOQ) is typically between 500 and 1,000 units per design. This is not an arbitrary number; it is dictated by the realities of the supply chain.

- Fabric Minimums: Our fabric mills have minimum dye lot requirements, often several hundred meters. Ordering less is either not possible or prohibitively expensive per meter.

- Production Line Efficiency: The setup costs for a production run (creating cutting dies, programming embroidery machines, training the assembly team) are substantial. Spreading these costs over a small run would make the per-unit price unfeasible.

The MOQ ensures we can source materials efficiently and operate our production lines cost-effectively, keeping your unit price competitive.

Quality Control and Safety Standards

Quality is built into every stage of our process, not just inspected at the end. Adherence to international safety standards is non-negotiable.

Quality Inspection Steps

- In-Line Inspections: Our QC team monitors the production line, checking for consistency in sewing, stuffing, and assembly to catch deviations early.

- Final AQL Inspection: After production, we conduct an inspection based on AQL (Acceptable Quality Limit) standards, a statistical sampling method to verify the quality of the entire batch.

- 100% Final Check: Every unit is visually inspected for cosmetic flaws, and loose threads are removed before packing.

- Metal Detection: Every plush toy passes through a metal detector to ensure no broken needle fragments or other metallic contaminants are present.

International Safety Standards (EN71/ASTM)

Your product must be legally compliant for your target market. The two primary standards are EN71 (Europe) and ASTM F963 (USA). These cover:

- Physical and Mechanical Tests: Pull tests on seams, eyes, and small parts to prevent choking hazards.

- Flammability Tests: Ensuring the material’s rate of flame spread is within safe limits.

- Chemical Analysis: Testing for heavy metals (lead, cadmium), banned phthalates, and other toxic substances.

A Note from the Factory Floor: Certification is product-specific. While our factory holds audits like BSCI and ISO9001, your specific plush toy must be independently tested by a certified lab (e.g., SGS, Intertek) to receive its own compliance certificate. We facilitate this process.

Logistics: From Factory to Warehouse

We manage the entire logistics process, from custom packaging to final shipment.

- Packaging: We can develop custom hang-tags, display boxes, and protective polybags for each unit. Master cartons are selected to withstand international transit.

- Shipping Terms (Incoterms):

- FOB (Free On Board): The most common option. We manage all costs to get your goods onto the vessel at the port of origin (e.g., FOB Ningbo). Your freight forwarder handles the rest.

- EXW (Ex Works): Your responsibility begins at our factory gate. You arrange for pickup and manage the entire shipping process.

We work with trusted freight forwarders to provide competitive quotes for sea or air freight and handle customs clearance.

How to Choose a Supplier

Selecting the right manufacturing partner is the most critical decision you will make. The lowest price often conceals risks like poor quality, communication breakdowns, and non-compliance.

B2B Buyer-Focused Insights:

- Common Problems Buyers Face: Vague communication, unexpected delays, inconsistent quality between the sample and bulk order, and failed safety tests.

- Risk of Low-Quality Factories: A cheap quote can lead to an entire shipment of unsellable products due to seam failures, incorrect colors, or safety hazards, destroying your budget and brand reputation.

- What Brands Look For: A true partner offers technical expertise, proactive communication, and a commitment to quality. They act as an extension of your team.

Vetting a Potential Manufacturer

Ask these critical questions:

- Can you show me recent EN71 or ASTM test reports for similar products? A reputable factory will provide these readily.

- Who will be my dedicated point of contact, and what is their technical background?

- Do you welcome third-party inspections? Confidence in their quality process means they will have no issue with external verification.

Look for a manufacturer focused on building a long-term partnership. Their success is intrinsically linked to yours. For more guidance, explore our list of reputable stuffed animal companies.

Why FunEnjoy is a Trusted Manufacturer

As a dedicated plush toy manufacturer, FunEnjoy provides more than just production services. We offer a partnership built on transparency, technical expertise, and a commitment to quality. The pet toy market in China is booming, driven by a growing class of consumers who treat pets as family—a trend you can explore further in this report on the China pet toys market. We help brands tap into this and other global markets by delivering exceptional products that are safe, compliant, and true to their vision.

Our process is designed to de-risk sourcing for our clients by providing clear communication, rigorous quality control, and decades of manufacturing experience. We have helped hundreds of brands bring their ideas to life, from initial concept to market-ready products. To see the range of what’s possible, explore our full range of custom stuffed toys.

Ready to bring your unique plush concept to life with a partner you can trust? The team at FunEnjoy PlushToys has decades of experience turning creative ideas into high-quality, market-ready products. Contact us today to get a quote within 24 hours.