Custom plush dolls are more than toys; they are tangible brand assets. For businesses, transforming a mascot or character into a custom plush doll is a powerful strategy for building an emotional connection with an audience. Unlike a fleeting digital advertisement, a well-manufactured plush becomes a lasting fixture in a customer’s life, creating a constant, positive reminder of your brand.

Market Overview: The Business Case for Custom Plush Dolls

The global demand for unique, personalized toys is driving significant market growth. This trend points directly to China, the undisputed hub for toy manufacturing. The country’s infrastructure is optimized for producing high-quality, cost-effective custom plush dolls at scale. Statistically, China accounts for approximately 58% of global toy exports, with its domestic stuffed and plush toy market valued at US$1.1 billion and projected to reach US$2.2 billion by 2034.

This data confirms that the consumer desire for custom toys is not a passing fad but a sustained market shift.

Benefits for Your Brand

Partnering with a capable manufacturer allows brands to capitalize on this demand. A custom plush line serves multiple strategic purposes:

- Retail Products: Develop a signature product line for e-commerce or physical stores.

- Promotional Merchandise: Create memorable, high-value giveaways for trade shows and marketing campaigns.

- Corporate Gifting: Strengthen relationships with key clients, partners, and employees.

- IP Monetization: Bring intellectual property from animations, games, or books into the physical world for fans to own.

From a manufacturer’s perspective, we observe daily how brands leverage plush toys to embody their story. A well-executed doll serves as a brand ambassador, carrying a company’s personality and values. Our case study about our partnership with Starbucks demonstrates this impact.

Understanding the production landscape is the foundational step toward making informed decisions, selecting a reliable partner, and creating a successful custom plush doll.

The Manufacturing Process: A Factory Floor Perspective

Bringing a custom plush doll from a 2D sketch to a 3D physical product is a precise, multi-stage process. Each step is critical for ensuring the final product matches the client’s vision in terms of quality, safety, and aesthetics.

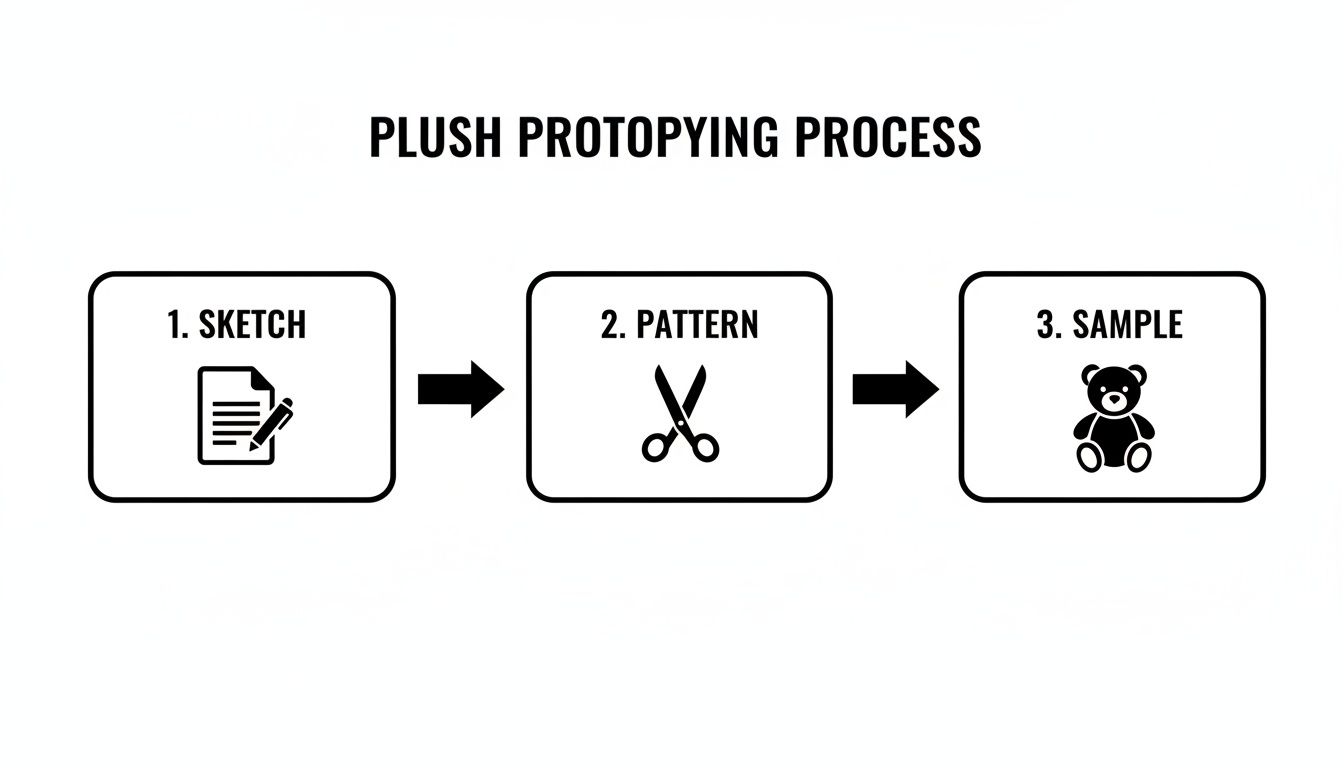

The Prototyping Journey: From Sketch to Physical Sample

The entire project begins with the “technical pack,” or tech pack. This document is the blueprint for your plush toy. An effective tech pack includes multi-angle vector drawings, precise dimensions, material specifications (e.g., fabric type, Pantone color codes), and detailed callouts for embroidery or printing. A vague brief leads to guesswork; a detailed tech pack ensures accuracy.

Once the tech pack is approved, our process is as follows:

- Pattern Making: Our pattern master translates the 2D drawings into a set of fabric patterns. This is a highly skilled craft that accounts for fabric stretch, seam allowances, and the final 3D form after stuffing. An imprecise pattern can result in a misshapen product.

- Material Cutting & Detailing: Fabric is cut by hand for the prototype to ensure precision. Details like embroidery or screen printing are applied to the flat fabric pieces before sewing for a clean, high-quality finish.

- Sample Sewing & Stuffing: Experienced sewers stitch the pieces into a three-dimensional “skin.” The sample is then stuffed with PP cotton. The amount and placement of stuffing are crucial—too little results in a flimsy feel, while too much can strain seams and create a hard texture.

- Review and Revision: We provide detailed photos and videos for client feedback. Specific comments like, “Increase stuffing in the torso by 15% for a firmer feel,” are far more effective than general feedback like, “It looks weird.” Each revision cycle typically adds 1-2 days to the timeline.

The typical sampling timeline, from receiving a complete tech pack to an approved sample, ranges from 5 to 10 working days, depending on design complexity and communication speed. This approved prototype becomes the “golden sample”—the quality standard that every unit in mass production must meet.

If you’re ready to get started, you can learn more about how to design your own plush toy and prepare a production-ready tech pack.

Inside the Factory: The Mass Production Workflow

With the golden sample approved, the factory floor shifts into mass production. The objective is to replicate the approved prototype with perfect consistency across hundreds or thousands of units.

- Stage 1: Material Preparation and Cutting: Large bolts of fabric are unrolled, stacked in layers, and prepared for cutting. We use two primary methods: die-cutting for simple shapes in large runs, where a hydraulic press stamps out pieces using a custom metal die, and computer-guided laser cutting for intricate designs, which also heat-seals fabric edges to prevent fraying.

- Stage 2: Sewing Assembly Line: The cut pieces move to the sewing floor, which operates as an assembly line. Each sewer specializes in a specific task—one attaches ears, the next joins the head to the torso. This division of labor ensures both speed and consistent quality. This process is a scaled-up version of the fundamental principles of how to sew a stuffed animal.

- Stage 3: Stuffing and Closing: A blowing machine fills the main body with a precisely weighed amount of PP cotton, guaranteeing consistent density.

Delicate parts like thin limbs or small ears are hand-stuffed by skilled workers using specialized tools to achieve the correct shape without stressing the seams.

The final opening is hand-sewn shut using a “hidden stitch” (ladder stitch) to create an invisible seam—a key indicator of a high-quality plush toy. - Stage 4: Final Touches and Inspection: Each doll is cleaned with air blasts and brushed to remove loose fibers. It then passes through a metal detector to ensure no stray needles are present. A final QC check confirms it matches the golden sample before packaging.

Pricing Factors: What Determines Your Unit Cost

The final unit cost of a custom plush doll is a sum of its parts. Understanding these cost drivers allows you to manage your budget effectively without sacrificing quality. The global market for stuffed animals is projected to hit US$26.23 billion by 2033, with an annual growth rate of 8.35%, driven by demand for custom products. This market data from globenewswire.com underscores the value of investing in a well-made custom plush line.

Key Cost Drivers

- Size and Complexity: Larger dolls require more material and filling. Complex designs with many individual pieces increase sewing time and labor costs. A simple, spherical character is inherently cheaper to produce than a detailed humanoid figure.

- Materials & Filling: Standard velboa plush is a cost-effective choice. Premium materials like minky, or fabrics requiring custom dyeing to match a specific Pantone, increase the unit cost. The type and amount of filling (e.g., standard PP cotton vs. recycled materials) also play a role.

- Embroidery and Printing: The cost of embroidery is calculated by stitch count. A simple eye may require a few hundred stitches, while a large, multi-color logo can require thousands. Each thousand stitches adds to the cost.

- Accessories: Items like clothing, hats, or props are mini-projects themselves, requiring separate patterns, materials, and assembly, which are factored into the final price.

Understanding Minimum Order Quantity (MOQ)

The Minimum Order Quantity (MOQ) is the smallest order volume a factory can process efficiently. For custom plush dolls, the industry-standard MOQ typically ranges from 100 to 500 pieces.

The MOQ is necessary for two primary reasons:

- Raw Material Procurement: Fabric and other materials are purchased in bulk from suppliers. The MOQ ensures that we can procure these materials without significant waste.

- Production Line Efficiency: Setting up the assembly line—creating patterns, calibrating machines, and training the team for a new design—has a fixed overhead cost. The MOQ allows us to amortize this setup cost across a sufficient number of units to keep the per-item price viable for the client.

A common question is, “Can you produce just 20 units?” While technically possible, the per-unit cost would be exceptionally high, as the full setup cost would be divided among only 20 pieces.

Quality Control & Global Safety Standards

Manufacturing a safe, durable, and compliant product is a manufacturer’s primary responsibility. Quality is not inspected at the end; it is built into every stage of the production process.

Our Multi-Stage Inspection Process

- Raw Material Inspection (IQC): Before production, all incoming materials are inspected for color consistency against Pantone specifications, correct texture and weight, and any defects.

- In-Process Quality Control (IPQC): QC inspectors monitor the assembly line, pulling random units to check seam strength, embroidery alignment, and component attachment. This allows for real-time correction.

- Final Quality Control (FQC): Every finished doll undergoes a 100% inspection. This includes cleaning, brushing, metal detection, and a final visual check against the golden sample before packaging.

Navigating EN71 and ASTM F963 Safety Standards

Compliance with international safety standards is mandatory for selling in major markets like the European Union (EN71) and the United States (ASTM F963). These certifications act as a passport for your product, ensuring it is legally cleared for sale and safe for children. We work with accredited third-party labs to conduct rigorous testing.

Key testing areas for plush toys include:

- Physical and Mechanical Tests: Seams, eyes, and other components are subjected to tension tests to ensure they do not detach and become choking hazards.

- Flammability Tests: Materials are tested to ensure they meet strict flame-spread resistance requirements, preventing them from being a fire hazard.

- Chemical Safety Tests: All components are screened for harmful substances like heavy metals (lead, mercury) and banned phthalates, ensuring the toy is non-toxic.

How to Choose a Supplier: B2B Buyer Insights

Selecting a manufacturing partner for your custom plush dolls is the most critical decision in this process. Focusing solely on the lowest unit price is a common but dangerous mistake that often leads to quality issues, missed deadlines, and hidden costs. A true partner provides reliability, expertise, and operational transparency.

OEM vs. ODM

- OEM (Original Equipment Manufacturer): You provide the complete, production-ready design (the tech pack), and the factory manufactures it to your exact specifications. This gives you full creative control.

- ODM (Original Design Manufacturer): You select a pre-existing design from the factory’s catalog and customize it with your branding (e.g., adding a logo). This is faster and requires less design work but offers limited originality.

What to Look for in a Supplier

- Factory Certifications: Verify certifications like ICTI (Ethical Toy Program) and BSCI (Business Social Compliance Initiative). These demonstrate a commitment to ethical labor practices, which protects your brand’s reputation.

- Proven Experience: Request a portfolio and case studies. A factory with a history of working with established global brands has proven its ability to meet high quality and compliance standards.

- Communication: During the quoting process, assess their responsiveness and clarity. Vague answers or slow replies are red flags. A professional partner communicates proactively and transparently.

Common Problems and The Risk of Low-Quality Factories

Choosing a low-cost, low-quality factory exposes your project to significant risks. We frequently onboard clients who have had negative experiences elsewhere.

The most common issue is the “bait and switch” on quality. A factory provides an excellent prototype to secure the order, then uses cheaper materials and rushes production to protect their thin margin, resulting in a final product that does not match the approved sample.

Other common problems include:

- Inconsistent Quality: Crooked seams, mismatched colors, and poor embroidery across the production run.

- Missed Deadlines: Delays that cause you to miss key retail launch dates.

- Hidden Costs: Unexpected fees for packaging, shipping, or failed QC inspections.

- Safety Failures: Use of non-compliant materials leading to failed EN71 or ASTM tests, making the entire shipment unsellable.

A reliable partner is an investment in your brand’s integrity. They function as an extension of your team, dedicated to protecting your investment and upholding your quality standards.

Tips to Reduce Cost Without Sacrificing Quality

- Simplify the Design: Reducing the number of unique pattern pieces or the complexity of embroidery directly lowers labor costs.

- Optimize Material Selection: Using high-quality in-stock fabrics instead of custom-dyed materials can offer significant savings.

- Increase Order Volume: Larger orders benefit from economies of scale in material purchasing and production efficiency, lowering the per-unit cost.

Ready to create a custom plush doll that people will love, with a partner you can count on? At FunEnjoy PlushToys, we bring decades of hands-on experience and a serious commitment to quality to every project.