A high-quality cotton doll is more than a toy; it is a meticulously engineered product, a synthesis of natural materials and skilled artisanship. For B2B buyers and global brands, selecting cotton is a strategic decision rooted in its superior tactile feel, inherent safety, and suitability for high-end, detailed designs. This guide offers a manufacturer's perspective on the entire production lifecycle, from initial concept to final shipment.

Inside the Modern Cotton Doll Manufacturing Landscape

From our position on the factory floor, the cotton doll sector represents a dynamic fusion of traditional craftsmanship and modern production technology. We observe a clear trend: major brands are increasingly specifying natural fibres for their merchandise. They understand that consumers associate "cotton" with quality and safety, particularly for products intended for children or the discerning collector market.

The intrinsic value of a cotton doll lies in its core material. It possesses distinct advantages over synthetic plush that resonate with both brands and their end customers:

- Superior Texture: Cotton offers a soft, breathable, and non-static touch that polyester fabrics cannot replicate.

- Hypoallergenic Properties: As a natural fibre, it is the preferred choice for sensitive skin, minimising the risk of allergic reactions.

- Design Versatility: Cotton textiles are exceptionally adaptable. Whether it's a smooth interlock for the doll’s skin or woven fabrics for apparel, the material accommodates a high degree of detail in both embroidery and construction.

The Heart of Production: China's Toy Ecosystem

China’s manufacturing ecosystem is the central pillar of the global plush toy industry. This is not merely about assembly; it is a deeply integrated supply chain providing access to specialised materials, a highly skilled workforce, and decades of production expertise. This network enables the reliable, large-scale manufacturing of premium cotton dolls.

Consider Yangzhou in Jiangsu province, the recognised global capital of plush toy production. This reputation is built on a long history of textile craftsmanship. By 2024, the region hosted over 500 specialised plush manufacturers, collectively accounting for an estimated 30% of China's total stuffed toy output.

At peak capacity, this translates to approximately 1.2 million units produced in the area daily. To understand the scale, explore more about China's toy market dynamics.

As a manufacturer, we view this ecosystem as a critical asset. When a client specifies a GOTS-certified organic cotton jersey or a unique embroidery thread, we can source it from trusted local suppliers within days. This proximity accelerates the development timeline and ensures material consistency across mass production runs.

Blending Craft and Technology

The creation of a modern cotton doll is a precise blend of art and industrial science. While computer-aided design (CAD) software facilitates the creation of accurate patterns and automated cutting machines ensure uniformity, the doll's character is imparted by human hands.

The subtle sculpting of facial features, the application of intricate embroidery, and the final assembly are all performed by skilled artisans who have honed their craft over years. This fusion of precision technology and traditional craftsmanship is what allows us to transform a 2D design sketch into a tangible, high-quality product that connects with consumers globally.

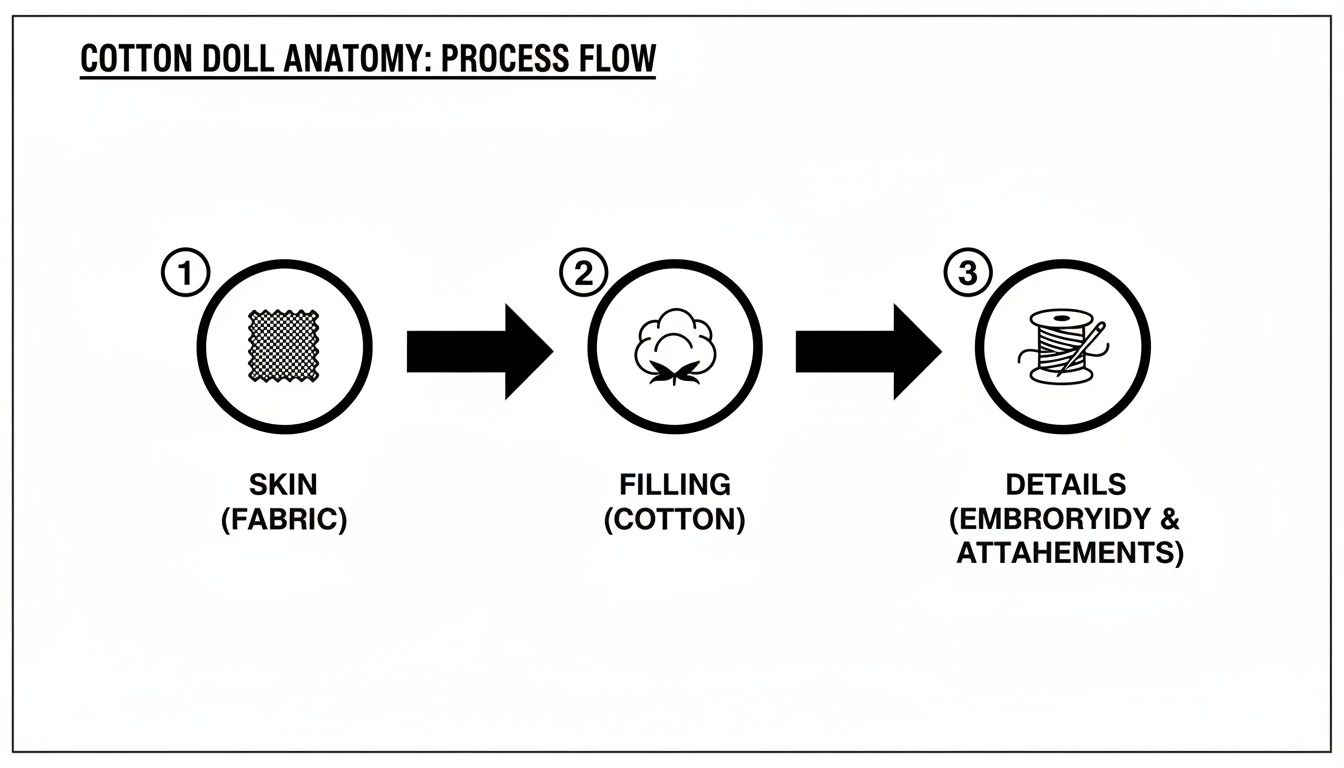

The Anatomy of a High-Quality Cotton Doll

To properly assess a high-quality cotton doll, one must look beyond aesthetics and understand its internal construction. As a manufacturer, we know each doll is an assembly of specific materials, each chosen for a distinct purpose. The final texture, durability, and safety are direct results of these foundational material choices.

The process begins with the fabric—the doll's "skin" and apparel. Not all cotton is created equal, and the specific type selected fundamentally defines the final product's look and feel.

The Fabric: Defining the Tactile Experience

The primary fabric imparts the doll's core personality. For the signature soft, smooth skin characteristic of high-end dolls, we exclusively use specific cotton knit fabrics.

- Organic Cotton Interlock: This is the premium standard for doll skin. It is exceptionally soft, possesses sufficient stretch for shaping detailed facial contours, and is hypoallergenic. Brands focused on sustainability or infant products often mandate GOTS-certified organic cotton.

- Cotton Jersey: Lighter than interlock, jersey is breathable and drapes well, making it ideal for doll apparel like miniature t-shirts and dresses. Its flexibility allows for the creation of detailed, realistic garments.

- Long-Staple Cotton: For woven components like a doll's shirt or trousers, we specify fabrics made from long-staple cottons such as Pima or Egyptian. The longer fibres yield a stronger, smoother fabric with a subtle lustre. Critically, it resists pilling, ensuring the doll maintains its premium appearance over time.

For doll hair, material options are diverse. Some clients prefer the natural aesthetic of cotton yarn. Others opt for materials like brushable mohair, which we crochet into a wig cap and affix to the head. This technique produces realistic, stylable hair.

The Filling: The Core of the Doll

The internal filling is as critical as the external fabric. The stuffing determines the doll's weight, posture, and "huggability." Achieving the right balance is a technical exercise in balancing feel, function, and cost.

The industry standard is polypropylene (PP) cotton. It is lightweight, resilient, and cost-effective, providing a classic plush feel. For more premium or specialised dolls, we incorporate other materials.

A common technique for high-end collector dolls is strategic weighting. We place weighted glass beads or plastic pellets within the doll's torso, hands, and feet. This provides a satisfying, realistic heft and enables the doll to sit upright or hold a pose without support.

Other fillings achieve specific effects:

- Memory Foam: We blend chopped memory foam with PP cotton to create a slow-rising, squishy texture that is currently in high demand.

- Wool Stuffing: For a 100% natural product, wool is an excellent, albeit more expensive, option. It is naturally flame-resistant and provides a firm, dense feel distinct from standard fillings.

The real expertise lies in the blend. We might use firm wool for needle-sculpting a detailed face, a soft PP cotton and memory foam mix for a squishable torso, and glass beads in the limbs to provide lifelike weight.

Comparison of Core Cotton Doll Materials

Selecting the right materials is the first step toward achieving product goals within budgetary constraints. This table breaks down the most common options we work with, designed to help you build a precise technical specification sheet for your next cotton doll project.

| Material Component | Type | Key Characteristics | Cost Impact | Best For |

|---|---|---|---|---|

| Doll Skin | Organic Cotton Interlock | Extremely soft, hypoallergenic, slight stretch. | High | Premium baby dolls, eco-conscious brands. |

| Doll Skin | Standard Cotton Jersey | Soft, breathable, good stretch. | Medium | General-purpose dolls, detailed clothing. |

| Doll Clothing | Woven Long-Staple Cotton | Smooth, durable, resistant to pilling. | High | High-end doll apparel, collector's items. |

| Filling | PP Cotton | Lightweight, fluffy, resilient, cost-effective. | Low | Standard plush toys, budget-conscious projects. |

| Filling | Weighted Glass Beads | Adds significant weight, improves posture. | Medium | Posable art dolls, collector's models. |

| Filling | Memory Foam Blend | Slow-rise, squishy texture. | Medium-High | Trendy "squishy" toys, sensory products. |

Ultimately, the optimal material combination is determined entirely by the intended product—whether a soft, simple companion for a child or a detailed, weighted collector's piece.

From Sketch to Shipment: The Complete Manufacturing Workflow

Transforming a 2D illustration into a high-quality, tangible cotton doll is a detailed, systematic process. It relies on meticulous planning, skilled craftsmanship, and transparent communication between the client and our factory team. Understanding this workflow is essential for setting realistic timelines, preparing design files, and making informed decisions.

At FunEnjoy Toys, we manage this entire process in-house, ensuring consistency and enabling us to implement rigorous quality control from the first fabric cut to the final sealed carton.

The entire operation follows a standardised, multi-stage path.

As illustrated, every component is critical. The choice of skin fabric, the type of embroidery thread, and the density of the filling all converge to create the final doll's appearance and tactile quality.

OEM Versus ODM: A Key Distinction

Before delving into the workflow, it is crucial to understand the two primary production models: OEM and ODM.

- OEM (Original Equipment Manufacturing): This is the path for a fully custom product. The client provides the complete design specifications, and we act as the manufacturing partner to bring that unique vision to life. The client retains full creative control.

- ODM (Original Design Manufacturing): This model offers a faster route to market. The client selects a pre-existing design from our catalogue, which we then customise with their branding, colours, or minor modifications.

The vast majority of our cotton doll projects are OEM. Brands typically approach us to create unique characters exclusive to their intellectual property. Therefore, the workflow detailed below is focused on the OEM process.

The Prototyping Stage: Translating Concept to Physical Form

This is the most critical phase of the project. We are creating the master sample—the physical blueprint for the entire production run. Any imprecision here will be replicated thousands of times, so meticulous accuracy is paramount.

- Design Finalisation and Pattern Making: The process begins with your 2D design file. Our master pattern maker, an artisan with decades of experience, translates this illustration into a series of 3D fabric patterns. This is an art form, requiring a deep understanding of how to capture a character's essence in textile form.

- Material Sourcing and Cutting: We then source the exact cotton fabrics, threads, and fillings specified in your tech pack. Upon approval, we use the patterns to cut the fabric pieces. For a single sample, this is done by hand. For mass production, we employ laser cutters to ensure perfect uniformity across every unit.

- Embroidery and Initial Assembly: Details define the doll. Features like eyes, mouths, and logos are embroidered onto the flat fabric pieces before they are sewn together. This is essential for achieving a clean, professional finish.

The creation of this first physical prototype and its shipment typically takes 5-10 days. This sample is sent directly to you for evaluation. You must review every detail—shape, size, materials, and overall quality.

Mass Production: The Factory Floor in Action

Once you approve the final prototype, we initiate mass production. This stage is defined by efficiency and stringent quality control.

The process mirrors the sampling stage but on a much larger scale, with specialised teams dedicated to each task. We establish assembly lines where one team handles sewing, another focuses exclusively on stuffing, and a third manages finishing touches like attaching accessories and trimming loose threads. For a more detailed look, see our guide on how plush toys are made.

A common challenge for new buyers is underestimating the number of prototype revisions required. Our standard timeline accommodates one to two revision rounds. Requesting numerous changes can significantly extend the pre-production phase and affect final delivery dates.

This structured workflow is the foundation of consistent quality. It supports the growing demand for fabric toys in China, a market projected to grow at a CAGR of 6.5% from 2025 to 2035. The cotton doll segment is a significant driver, expected to account for 44.1% of fabric toy revenue in 2025, largely fueled by parental demand for safe, natural materials.

From the initial design review to the final packaged doll, the entire process—including sampling and mass production—typically takes 25 to 40 days, depending on order quantity and design complexity. This timeline ensures we never compromise on quality control, which is integrated into every step.

Navigating Production Costs and Minimum Order Quantities

Understanding production costs is fundamental to effective budget planning. The unit price of a custom cotton doll is determined by several key factors: material selection, design complexity, custom accessories, packaging, and order volume.

- Material Selection: The choice of fabric and filling is a primary cost driver, potentially influencing the base cost by up to 30%.

- Design Complexity: An intricate doll with numerous components requires more labour hours and a higher embroidery stitch count, increasing the cost.

- Custom Accessories: Components like custom buttons, detailed embroidery, or bespoke packaging may incur one-time setup and tooling fees.

- MOQ Levels: Order volume directly impacts unit price. Larger orders enable economies of scale, resulting in lower per-unit costs.

- Packaging Specifications: The final packaging, from a simple polybag to a custom-printed gift box, contributes to the total cost.

With this foundation, let's examine MOQs.

In our facility, labour costs are calculated based on stitch time, design complexity, and the number of assembly steps. For a typical production run of 500 units, labour costs average approximately $2.00 per doll. Additionally, setup fees for tooling and die-cut plates for printed labels can add $100–$200 to the total project cost.

How MOQ Impacts Pricing

MOQ, or Minimum Order Quantity, is the smallest production run a factory will accept.

While some factories may offer smaller runs, sometimes as low as 100 pieces, this comes at a premium—unit costs can be 20–25% higher. This is because fixed setup costs are amortised over fewer units.

Scaling up to a standard MOQ of 500–1,000 pieces unlocks significant cost efficiencies. Factories can procure materials in bulk at discounted rates and optimise production lines, reducing overhead and, consequently, your per-piece price.

"For every 100-unit increase in your MOQ, you can expect an approximate 2–3% reduction in the unit price," notes our production manager.

Here are practical strategies for leveraging your MOQ:

- Consolidate Orders: If you have multiple designs or colourways, group them into a single, larger order to reach a higher MOQ tier.

- Simplify Colourways: Reducing the number of colours can minimise fabric waste during the cutting process, helping to control costs.

- Negotiate Split Shipments: If cash flow or inventory space is a concern, ask if the factory can produce the full MOQ but deliver it in staggered shipments.

Explaining Material and Design Cost Drivers

Fabric selection is one of the most significant cost variables. For instance, a premium organic cotton interlock can be 30–40% more expensive than a standard cotton jersey.

The same principle applies to filling. Basic PP cotton is the most economical option, whereas specialty fillings like memory foam or weighted beads can add 10–15% to the unit cost.

- Cotton Jersey (Medium Cost): A versatile choice for doll clothing, offering breathability and good drape.

- Organic Interlock (High Cost): The premium option for an ultra-soft, stretchy feel.

- PP Cotton (Low Cost): The industry standard for stuffing; lightweight and resilient.

- Memory Foam (Medium Cost): Adds a unique, slow-rising sensory quality.

- Weighted Beads (Medium Cost): Provides a satisfying heft and improves the doll's ability to sit upright.

Here is a comparison of how these choices impact cost:

| Feature | Basic Model | Premium Model |

|---|---|---|

| Fabric | Cotton Jersey | Organic Cotton Interlock |

| Filling | PP Cotton | Memory Foam + Weighted Beads |

| Embroidery Stitches | ~200 | ~600 with multi-colours |

| Unit Cost Impact | Baseline | +25% |

| MOQ | 100 | 500 |

Accessories and packaging are other areas to monitor. Custom-branded buttons often require a minimum tooling fee. Packaging can range from an inexpensive polybag to a full-colour, custom-designed gift box.

To reduce packaging costs:

- Use standard-sized polybags and arrange for bulk printing.

- Simplify swing tag designs to a single colour.

- Order unbranded boxes and apply your own branded labels upon receipt.

Strategic packaging choices can reduce your total landed cost by 5–8%.

For more insights, our guide on wholesale plush toys for B2B buyers provides additional detail.

Practical Negotiation and Cost Trade-Offs

Effective negotiation can reduce costs without compromising quality.

Be aware that some factories may have hidden fees for services like creating digital printing plates or changing thread colours mid-production. The best way to mitigate this is by providing a highly detailed technical specification sheet from the outset. This minimises ambiguity and prevents unexpected charges.

Common pitfalls to avoid during negotiation:

- Vague colour specifications leading to multiple, costly sample remakes.

- Last-minute design changes that may incur rush fees.

- Undefined packaging dimensions, resulting in material waste.

Here's a brief case study: one client simplified their embroidered logo from five colours to two. This single change reduced the stitch count by 40% and resulted in a $0.50 saving on every unit.

Balancing Quality and Cost

While choosing the lowest-cost factory is tempting, it often introduces significant risks. Poor quality control can lead to defect rates exceeding 5%, resulting in rework costs and shipment delays.

To protect your investment, always request in-line inspection photos during production. Additionally, use AQL (Acceptable Quality Limit) standards to clearly define your tolerance for minor defects.

Summary of Key Takeaways

Understanding your cost drivers and MOQ is about making strategic, informed decisions for your brand.

Material and design choices constitute over 60% of your unit cost. Proactive planning with clear specifications and strategic negotiation can eliminate hidden fees. Optimising packaging can yield a 5–8% reduction in your landed costs.

Ultimately, cost transparency fosters a stronger partnership with your manufacturer. Always insist on a detailed cost breakdown covering materials, labour, and setup fees before finalising any agreement.

Meeting Global Safety Standards and Quality Control

For a product as intimate as a cotton doll, quality and safety are non-negotiable. A single production error or a failed safety test can cause irreparable damage to a brand's reputation. A rigorous, multi-stage quality control (QC) process is therefore the foundation of any reputable manufacturing operation.

From our perspective on the factory floor, QC is not a final inspection; it is a continuous process integrated into every stage of production. It begins with the receipt of raw materials and concludes only when the final carton is sealed for shipment. This is the only method to ensure consistency and safety across thousands of units.

International Safety Standards Demystified

Navigating global safety regulations is a standard operational procedure for an experienced manufacturer. For Western markets, two primary standards are critical: EN71 for Europe and ASTM F963 for the USA.

These standards mandate specific, objective tests that a doll must pass.

- Physical and Mechanical Tests (EN71-1 / ASTM F963): This includes pull tests on seams, eyes, and any attached accessories. The objective is to ensure no component can detach and become a choking hazard. We use calibrated tension gauges to apply a precise force, ensuring every part can withstand significantly more pressure than a child could exert.

- Flammability Test (EN71-2 / ASTM F963): A fabric sample from the doll is exposed to a controlled flame. We measure the rate of spread of the flame. To pass, the material must self-extinguish within a specified time, preventing a small spark from becoming a significant hazard.

- Chemical and Heavy Metal Analysis (EN71-3 / ASTM F963): Material samples are tested for harmful substances like lead, cadmium, and phthalates. This is particularly crucial for dyed fabrics and any printed elements on the doll.

A common error for new buyers is assuming a supplier is compliant. Always request recent test reports for the specific materials being used in your product. A legitimate factory will provide these documents without hesitation as proof of their commitment to safety.

The Multi-Stage QC Inspection Process

An effective QC system is designed to identify issues early, saving costs, reducing waste, and maintaining the production schedule. Our process is divided into three critical checkpoints.

- Incoming Quality Control (IQC): Before any material enters the production line, our IQC team conducts a thorough inspection. They verify that fabric colours match the specified Pantone standard, check fibre consistency, and ensure stuffing is clean and free of contaminants.

- In-Process Quality Control (IPQC): During assembly, line supervisors continuously monitor the work. They look for common defects such as misaligned stitching, inconsistent stuffing density, or off-centre embroidery. Any unit that fails to meet the standard is immediately removed from the line for correction.

- Final Quality Control (FQC): Before packaging, each doll undergoes a final, meticulous inspection. This is the last opportunity to catch any defect, from a loose thread to a minor cosmetic blemish. We use an AQL (Acceptable Quality Limit) system to maintain an extremely low defect rate.

China's cotton doll industry expanded significantly after 2000, with cities like Yangzhou becoming global production centres. This deep expertise forms the basis of a market that is part of a US$3.53 billion global industry. At FunEnjoy Toys, we have been part of this evolution, manufacturing high-quality custom stuffed animals and dolls for major global brands since 1993. For more context, you can review this guide on China's powerful toy import market. Our experience has taught us that preventative, rigorous QC is the most effective way to protect our clients' brands and deliver a product that is safe, durable, and true to their vision.

How to Choose the Right Manufacturing Partner

Selecting a manufacturing partner for your cotton doll is one of the most critical business decisions you will make. A great factory functions as an extension of your team, whereas a poor one can lead to delays, quality issues, and reputational damage. While a low price is appealing, it should never be the sole evaluation criterion.

From our experience, the most successful partnerships are built on technical expertise, reliability, and clear communication. A rock-bottom quote often signals compromises in these areas, which ultimately incurs higher costs in the long run.

Evaluating Technical Expertise and Communication

The initial test of a potential partner is their communication protocol. Do they respond to inquiries promptly? Are their answers to technical questions clear and detailed, or vague? A manufacturer who communicates effectively from the outset is more likely to be a reliable partner during production.

Next, assess their technical capabilities by reviewing their past work.

- Look for similar work: Ask to see examples of cotton dolls they have produced with similar materials or construction techniques to your design.

- Talk through challenges: Present a complex aspect of your design and ask how they would approach its production. A competent team will offer practical, viable solutions.

- Get the details on their sampling process: Inquire about their sampling fees, timelines, and the number of revision rounds included. This provides insight into their attention to detail and client service process.

A significant positive indicator is a factory's willingness to conduct a technical design review before providing a quotation. An experienced manufacturer will identify potential production challenges early, such as embroidery that is too fine to be stitched cleanly or a seam placement that could compromise durability.

Verifying Certifications and Factory Audits

Never accept claims at face value. Always request documentation to verify assertions about quality and ethical standards. This is not a bureaucratic formality; it is a crucial step in protecting your brand and ensuring your products are manufactured safely and responsibly.

Request copies of these key documents:

- Quality Management System (ISO 9001): This certification demonstrates that the factory has documented, repeatable processes for maintaining quality.

- Social Compliance Audit (BSCI or Sedex): These reports verify that the factory adheres to ethical labour practices, including fair wages and safe working conditions.

- Recent Material Test Reports: Ask for current EN71 or ASTM test reports for the specific cotton and filling materials you intend to use.

If feasible, arrange for a third-party factory audit or visit in person. Direct observation of the production line, meeting the team, and seeing their processes firsthand provides a level of assurance that no document can match. This due diligence is essential for making a low-risk, informed decision for your brand's next major project.

Answering Your Top Questions About Cotton Doll Manufacturing

For those new to custom cotton doll production, the process can seem complex. Over decades of working with brands, we have found that a few key questions consistently arise.

Here are the answers to the most common inquiries we receive.

How Long Does It Take to Make a Custom Doll?

From final design approval to readiness for shipment, the typical production timeline is 25 to 40 days.

This is divided into two main phases:

- Sample Development: Creating the prototype, which includes pattern making, material sourcing, and assembling the first physical unit. This stage generally takes 5 to 10 days.

- Mass Production: Once the sample is approved, manufacturing the full order quantity. Depending on the order size and design complexity, this requires an additional 20 to 30 days.

This timeline is structured to allow for meticulous attention to detail and quality control at every step, ensuring a high-quality outcome without rushing the process.

Can I Start with a Smaller Order Than 500?

Yes. While our standard minimum order quantity (MOQ) is 500 pieces—the optimal volume for cost-efficiency—we recognise that many brands need to start smaller. We can often accommodate orders as low as 100 pieces.

It is important to note that with smaller production runs, the per-unit cost will be higher. This is because fixed setup costs (pattern making, machine calibration) are distributed over fewer units.

For new brands or for testing a new design, a smaller initial order is a prudent strategy. Once market demand is validated, scaling up to 500 pieces or more on subsequent orders will significantly improve profit margins.

What are the Biggest Pitfalls to Avoid in Production?

Based on our extensive experience, the most common and costly problems stem from a single source: unclear technical specifications. Vague design files or incomplete material details inevitably lead to delays and unforeseen costs during the sampling phase.

The most effective way to prevent this is to provide a comprehensive "tech pack" at the project's inception. This document should include:

- Clear, multi-view illustrations of your doll (front, back, and side profiles).

- Specific Pantone colour codes for all fabrics and embroidery threads.

- Precise material specifications (e.g., "GOTS-certified organic cotton interlock" rather than just "cotton").

Investing time in creating a crystal-clear technical brief at the beginning is the single most important action you can take to ensure a smooth production process and a final product that perfectly matches your vision.

At FunEnjoy Toys, our function is to translate your creative vision into a tangible, high-quality plush product. If you are ready to develop a cotton doll collection, we have the expertise and infrastructure to execute your project with precision and reliability. Learn more and get a quote today.