Plush Toy with Voice Recorder manufacturing combines two distinct crafts: traditional plush toy making and electronics integration. This combination transforms a simple toy into a personal, interactive product, but it requires specialized factory-level expertise to execute correctly. This guide provides an in-depth look at the manufacturing process, from a factory floor perspective, for B2B buyers looking to develop and source these products.

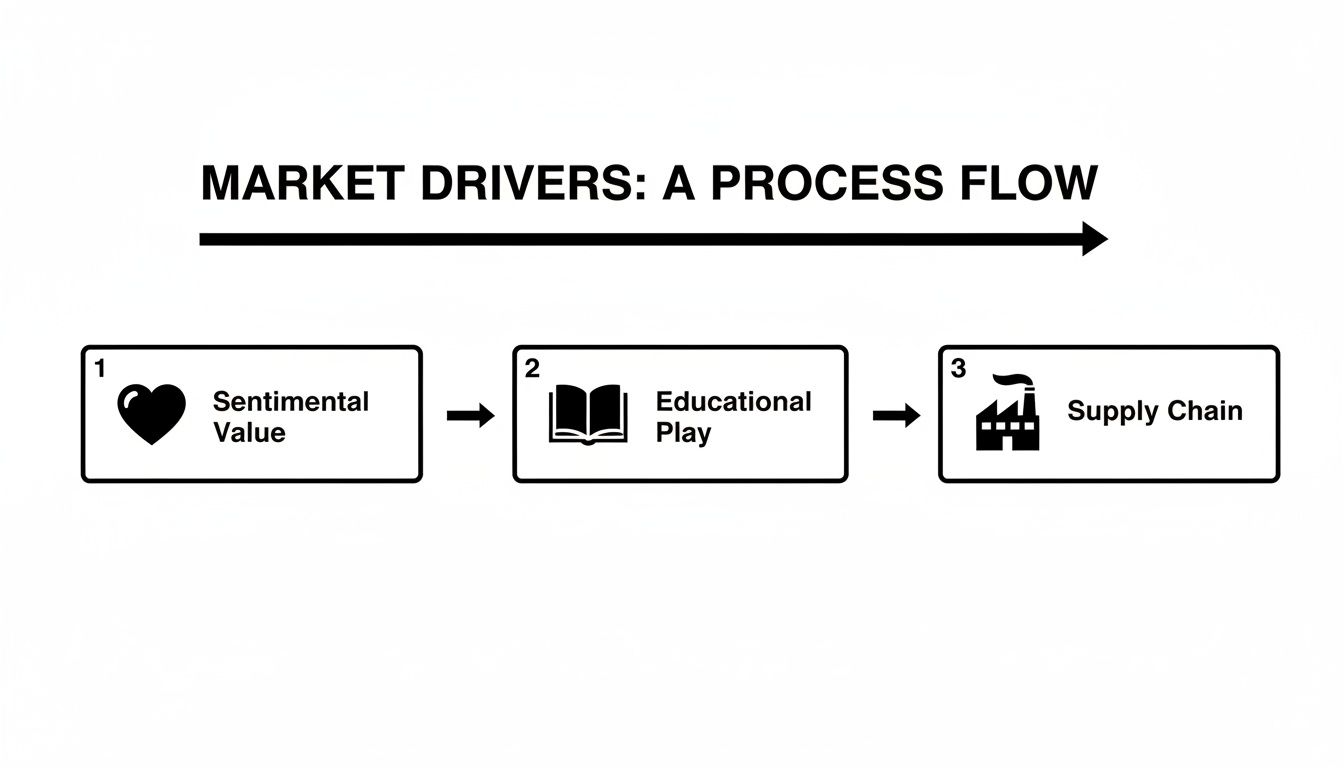

Market Overview: Why Voice-Enabled Plush Toys Are a Growing Sector

From our production lines in China, we have a direct view of market demand. The trend for plush toys with voice recorders is not temporary; it’s a sustained shift towards products that offer a deeper, personal connection.

Sentimental Value and Educational Play as Market Drivers

A significant portion of our orders is driven by sentimental value. These toys often carry recorded messages from loved ones, turning a standard plush into a cherished keepsake. This emotional component is a powerful market driver.

Simultaneously, we are fulfilling more B2B orders for educational toys. Brands are using voice modules to teach words, sing songs, or provide interactive instructions. This has expanded the toy’s application and value, pushing demand from basic 10-second recorders to more complex modules with higher fidelity and longer storage.

Industry data validates our observations. In 2023, China’s stuffed and plush toy market was valued at USD 976.3 million and is projected to reach USD 1,729.1 million by 2030, with a CAGR of 8.5%. Electronic integration is a major contributor to this growth. You can read the full research about these market trends.

From a manufacturing standpoint, the most successful products balance emotional appeal with reliable technology. A high-quality recording inside a well-crafted plush toy creates an experience that standard toys cannot match.

The Role of China’s Supply Chain

This market growth is supported by robust supply chains in manufacturing hubs like Shenzhen and Ningbo. These regions host specialized ecosystems of suppliers for electronic modules, providing pre-certified voice recorders that meet global safety standards. This concentration of expertise allows us to focus on our core competency: designing, crafting, and seamlessly integrating electronics into the plush exterior, resulting in faster and more reliable production for our clients.

The Manufacturing Process: From Tech Pack to Final Product

The journey from a digital design to a physical product is a multi-stage process grounded in precision and quality control. It begins with the client’s tech pack, which serves as our manufacturing blueprint.

Step 1: Sampling (The Prototype Stage)

The tech pack details everything: dimensions, materials, Pantone colors, and the precise placement of the sound module. Our sampling team uses this to create the first physical prototype. This is a critical milestone where the concept becomes a tangible item for evaluation and refinement. Typically, this stage involves one or two rounds of revisions to ensure every detail is perfect before mass production.

Step 2: Material Sourcing and Cutting

Once the prototype is approved, we move to mass production. The process starts in the cutting department. Based on the approved patterns, we fabricate precise steel cutting dies. These dies stamp out fabric panels from large rolls, ensuring absolute uniformity across thousands of units. Simultaneously, we procure all other materials, including the electronic voice modules, PP cotton filling, and any custom accessories.

Step 3: Embroidery and Printing

All detailing, such as embroidered eyes or screen-printed logos, is done while the fabric panels are still flat. This allows for greater precision and a cleaner finish compared to applying details to a three-dimensional, assembled toy.

Step 4: Sewing and Electronics Integration

On the sewing line, our workers stitch the fabric panels together, intentionally leaving a small opening for stuffing and the electronics. A separate team prepares the voice recorder modules.

Here is our standard procedure for electronics integration:

- Protective Pouch: The voice recorder is placed inside a small, stitched fabric pouch. This acts as a safety buffer, shielding the electronics from stuffing fibers.

- Button Alignment: The activation button is carefully positioned against the inner surface of the plush “skin” as specified in the tech pack—commonly a paw or the abdomen.

- Secure Placement: The entire pouch assembly is inserted into the toy and sewn directly to an internal seam. This prevents the module from shifting, a common failure point in low-quality products.

A frequent shortcut taken by subpar factories is to simply drop the voice module into the toy. This saves a few seconds per unit but inevitably leads to the button becoming misaligned and difficult to press. Our method ensures it remains in the correct position permanently.

Step 5: Stuffing and Finishing

With the electronics securely in place, the toy is filled with PP (polypropylene) cotton using specialized blowing machines for a consistent fill. Our operators control the density to ensure the toy is firm enough to hold its shape yet soft enough for cuddling. The final opening is then hand-stitched closed using a hidden stitch that is nearly invisible.

This process balances sentimental appeal with efficient and safe manufacturing.

If you’re interested in a more comprehensive look at our craftsmanship, you can learn more about our production process.

Pricing Factors: What Drives the Cost of Your Voice Recorder Plush Toy?

The unit cost of a custom plush toy with a voice recorder is determined by a series of specific manufacturing choices. Understanding these factors allows B2B buyers to make informed decisions that align with their budget and product goals.

The voice recorder module itself is often the most significant cost driver. A basic 10-second playback-only module is an economical component. In contrast, a 60-second, high-fidelity, re-recordable module can increase the component cost by 30-50%.

Material Choices and Design Complexity

The second major cost factor is the fabric. Standard polyester plush is a cost-effective choice. Premium materials like super-soft minky fabric or custom-dyed velboa increase the unit price due to higher raw material costs and the minimum order quantities imposed by our fabric suppliers.

Design complexity directly impacts labor costs. A simple, spherical plush toy might require only six fabric panels. A detailed character with articulated limbs, clothing, and facial features could require over 20 individual panels. More panels translate to more cutting, intricate stitching, and increased labor time from our skilled sewing teams.

Embroidery costs are calculated by stitch count. A simple logo may require 1,500 stitches, while a complex, multi-color character face can exceed 10,000 stitches, consuming more machine time and resources.

The Voice Module Supply Chain

Voice recorder modules have become a specialized industry within China’s toy accessory market. Hubs like Shenzhen and Ningbo produce millions of units monthly, engineered to meet safety standards such as CE, FCC, and EN 71-3. This niche has seen 15-20% year-on-year growth, with 60-second re-recordable models becoming a popular B2B choice. You can find more market data on the voice recording plush toy market on GlobalSources.com.

Key Factors Influencing Unit Cost

| Cost Factor | Low-Cost Option (Example) | High-Cost Option (Example) | Typical Price Impact (%) |

|---|---|---|---|

| Voice Module | 10-second playback-only | 60-second re-recordable, high-fidelity | 30-50% |

| Fabric | Standard polyester plush | Custom-dyed minky fabric | 15-25% |

| Design Complexity | Simple round shape (6 panels) | Detailed character (20+ panels) | 20-40% |

| Embroidery | 1,500-stitch logo | 10,000-stitch detailed face | 5-15% |

| Stuffing | Standard PP cotton | Recycled or hypoallergenic filling | 5-10% |

Safety Testing and Quality Control Costs

Costs for safety and quality are non-negotiable and built into every quote.

- Safety Testing: Certification for EN71 (Europe) or ASTM F963 (USA) requires third-party lab testing. This covers chemical analysis, mechanical strength of seams, and battery compartment security.

- Quality Control (QC): Our multi-stage QC process includes inspecting raw materials upon arrival, in-line inspections during production, and a 100% final inspection of every completed unit.

Cutting corners on these aspects may yield a lower initial quote but exposes a brand to significant risks, including product recalls, safety failures, and reputational damage.

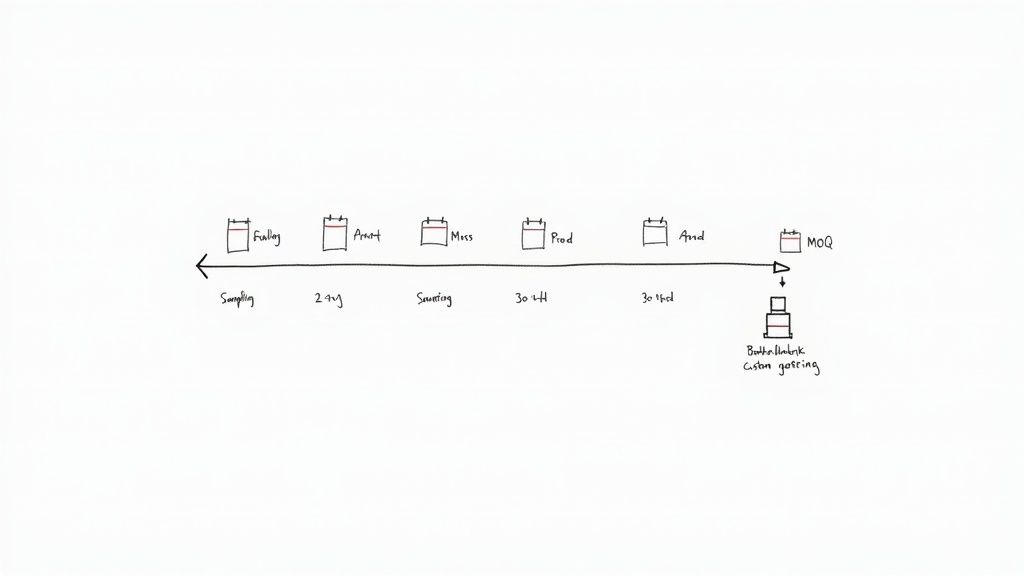

MOQ and Production Timelines: A Realistic Guide

Minimum Order Quantities (MOQs) and production timelines are practical realities of custom manufacturing, dictated by supply chain constraints and production line efficiency.

Understanding Minimum Order Quantities (MOQs)

For a custom plush toy with a voice recorder, our typical MOQ is between 500 and 1,000 units. This range is necessary to efficiently source custom-dyed fabrics and specialized electronic modules. Setting up production—calibrating cutting dies, programming embroidery machines, and dedicating a sewing line—involves fixed costs that are only commercially viable when amortized over a sufficient number of units.

For clients requiring smaller runs, we offer solutions:

- Use In-Stock Materials: Selecting fabrics and colors we already have in our warehouse is the most effective way to lower the MOQ, as it eliminates the need for a large, custom order from our suppliers.

- Simplify the Design: A less complex design may allow us to bundle production with other orders using similar sewing techniques.

- Choose Standard Components: Using a common voice recorder module that we keep in stock provides greater flexibility.

Manufacturer’s Warning: Be cautious of factories offering unusually low MOQs (e.g., 100 units) for a fully custom design without a clear explanation. This often indicates compromises on material quality or hidden downstream costs.

A Realistic Production Timeline

A well-planned timeline is essential for a successful product launch. Rushing any stage typically leads to quality compromises.

Sampling (2–3 weeks)

This phase involves creating the physical prototype from your tech pack, including pattern making, sample sewing, and fitting the voice recorder. It typically includes 1-2 rounds of revisions.

Material Sourcing (2–4 weeks)

Upon sample approval, we order all raw materials. This process often runs concurrently with final sample revisions to save time.

Mass Production (30–45 days)

This is the core manufacturing phase: cutting, embroidery, sewing, electronics installation, stuffing, and finishing. The duration depends on design complexity and order volume.

Potential Delays:

- Custom-dyed fabric: Adds at least 10-14 days for lab dip approvals and dyeing.

- Custom plastic parts (e.g., eyes, nose): Creating a new mold can add 20-30 days.

We identify and communicate these potential bottlenecks at the outset to ensure transparent project planning. For higher volumes, understanding our capacity for plush toys wholesale can aid in scheduling and identifying potential volume discounts.

Quality Control and Adherence to Global Safety Standards

Integrating electronics into a plush toy elevates the importance of safety and quality. Our approach embeds these principles into every stage of production, not just a final check.

Multi-Stage Inspection Process

- Raw Material Inspection: All incoming materials are inspected. Fabric rolls are checked for color consistency and flaws. A random sample of voice modules from each batch is tested for sound clarity, recording function, and battery life.

- In-Line Inspection: Our QC teams monitor production on the factory floor. We conduct pull-tests on seams, check stitch density, and verify that electronics are installed correctly within their secured pouches.

- 100% Final Inspection: Every single finished plush toy with a voice recorder is individually inspected. We test the activation button, confirm sound quality, and perform a final seam strength check before packing.

Compliance with EN71 and ASTM F963

We engineer all products to meet the most stringent international safety standards, providing our clients with market-ready goods.

A product failing safety tests is a catastrophic risk to a brand’s reputation. We don’t just aim to pass; we build safety into the product’s design from the very beginning.

The two primary standards we adhere to are:

- EN71 (Europe): This comprehensive standard covers mechanical properties (ensuring no small parts detach), flammability, and chemical safety. We ensure all dyes, fabrics, and plastics are free from prohibited substances.

- ASTM F963 (USA): This is the mandatory safety standard in the United States. It includes rigorous testing for sharp points, choking hazards, and lead content. For electronic toys, it places critical emphasis on the security of the battery compartment, which must require a tool (like a screwdriver) to open.

Proactive compliance with these standards ensures every toy is safe from chemical, physical, and fire hazards. To see this commitment across our product lines, you can explore our collection of stuffed animals and plush toys.

How to Choose a Supplier: OEM vs. ODM and Key Vetting Questions

Selecting the right manufacturing partner is the most critical decision in this process. A reliable factory acts as an extension of your team. The vetting process must focus specifically on their experience with electronic toys, as this requires a higher level of technical skill and quality control than standard plush manufacturing.

Key Questions to Ask a Potential Supplier

Go beyond basic questions about price and capacity. Dig into their specific processes for electronic toys. Vague answers are a significant red flag.

- “Describe your process for testing voice modules, both before and after installation.” A competent factory will detail a multi-stage process: batch testing modules upon arrival and a 100% functional test on every finished toy.

- “Can you provide case studies or examples of electronic plush toys you have manufactured for clients in the US or EU?” This verifies their experience with major international markets and their respective safety standards.

- “How do you secure the voice recorder and battery compartment to comply with ASTM F963 and EN71?” Look for specific answers, such as using a secured pouch stitched to an internal seam and a battery case requiring a tool for access.

- “Can you share your latest factory audit reports, such as BSCI or Sedex?” Reputable factories are transparent about their operational standards and ethical practices. Refusal is a serious concern.

The quality and detail of their answers reveal their expertise. Hesitation or generic responses likely indicate a lack of experience or transparency.

OEM vs. ODM: Which Service is Right for You?

Understanding the difference between these two service models is key to finding the right fit.

OEM (Original Equipment Manufacturer): This model is for clients who have a complete, unique design. You provide a detailed tech pack, and we manufacture the product to your exact specifications. This offers maximum creative control but requires significant upfront design work.

ODM (Original Design Manufacturer): This model is ideal if you have a concept but not a finalized design. You can select one of our existing plush toy designs and customize it by changing colors, adding your branding, and integrating the required voice recorder. ODM is often a faster, more cost-effective way to bring a product to market.

A capable manufacturer should offer both OEM and ODM services and guide you toward the best path for your project and budget.

FAQs from B2B Buyers

We regularly address these practical questions from our clients during the production process.

How long does the battery last?

Most voice modules use replaceable AG13 or LR44 button-cell batteries, which are designed for hundreds of playbacks and typically last at least one year under normal use. To preserve battery life during shipping and retail, each unit is shipped with a plastic pull-tab that prevents the battery from activating until removed by the end consumer. For premium products, we can integrate larger battery packs or rechargeable options with a concealed USB port.

Can the customer record their own message?

Yes, this is a core feature for many products. We typically install re-recordable modules that allow the end-user to record a new message by pressing and holding a button, often concealed in a paw or ear. For products requiring a permanent message, such as promotional items or branded characters with catchphrases, we offer single-record modules. We pre-load the audio file at the factory, and it cannot be overwritten.

Our Safety Protocol: The voice recorder is housed in a durable plastic case. This case is then placed inside a stitched fabric pouch, which is securely sewn to an internal seam of the toy. This double-layer protection makes the electronics inaccessible to a child, ensuring compliance with strict safety standards like EN71 and ASTM F963.

At FunEnjoy PlushToys, we manage these technical specifications daily. Our expertise ensures your plush toy is not only engaging but also safe, durable, and manufactured to the highest standards. If you are ready to discuss your project, please get in touch with our team.