Turning a sketch into a cuddly, three-dimensional friend is a complex partnership between a brand’s creative vision and a manufacturer’s hands-on expertise. From our perspective on the factory floor in China, success hinges on precise design translation, intelligent material choices, and an unwavering commitment to quality control.

This guide pulls back the curtain on the entire manufacturing journey. We will walk through the workflow, from a simple drawing to a mass-produced product ready for global markets, providing the practical, manufacturer-level knowledge B2B buyers need.

From Concept to Cuddles: The Stuffed Toy Journey

Bringing a plush toy to life is a multi-stage industrial process, meticulously planned to ensure every unit is safe, consistent, and true to the original concept. For brands and creators, understanding this workflow is the single most critical factor for a successful product launch. It demystifies manufacturing and empowers you to make informed decisions.

This is not a niche market. In 2023, the stuffed and plush toy market in China generated a staggering USD 976.3 million in revenue, with significant projected growth. The largest segment by far is stuffed animal toys, accounting for nearly 36% of that total. You can explore the data behind the growth of the plush toy market to understand the scale of the opportunity.

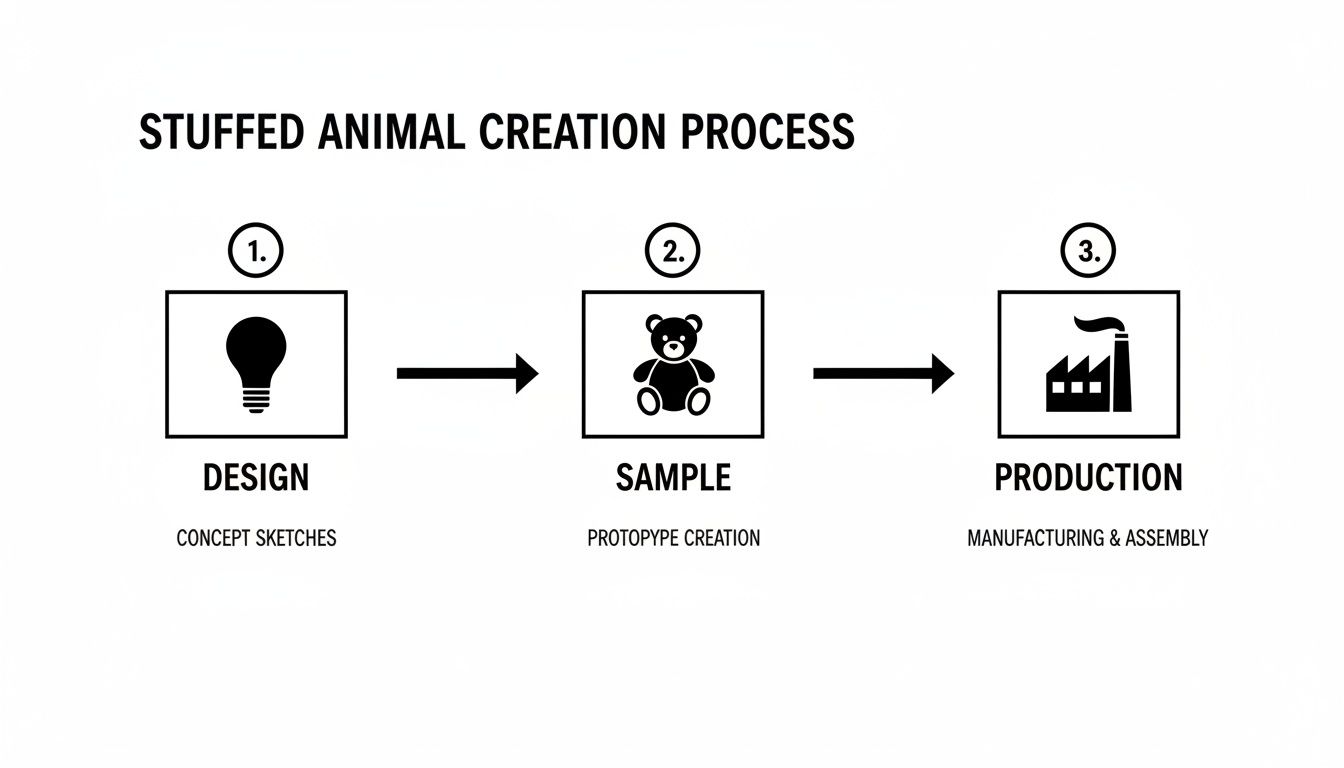

The Three Core Stages of Production

The entire manufacturing workflow can be broken down into three sequential phases. Each stage builds directly on the previous one, making early precision essential to avoid costly errors later. From a factory’s viewpoint, getting the details right at the design and sample stage is paramount.

This chart illustrates the fundamental flow:

As shown, a solid design is the blueprint for an accurate sample. That physical sample then becomes the non-negotiable standard for the entire mass production run.

To navigate these stages effectively, B2B buyers must become familiar with key manufacturing concepts. You will encounter terms like OEM and ODM, need to understand Minimum Order Quantities (MOQs), and, most critically, ensure your final product complies with all mandatory global safety standards.

From my experience managing production lines, the most successful projects arise from strong collaboration. When a client provides a clear technical specification and understands the basic manufacturing realities, we can work together to create exceptional stuffed animal toys efficiently and within budget.

In the following sections, we will dissect each part of this process: the hands-on sampling stage, the mechanics of mass production, and the critical quality control checkpoints that protect both consumers and your brand’s reputation.

Perfecting the Prototype Before Production

This is the moment of truth, where your vision for your stuffed animal toys transitions from a 2D technical drawing into a tangible object. Prototyping is an essential iterative dialogue between your design and the physical constraints of manufacturing.

The process begins with our master pattern maker, a role that requires years of experience to translate a 2D design into 3D fabric panels. They create precise paper masters for each component, meticulously calculating seam allowances and curves to achieve the correct shape and scale.

Once the pattern is finalized, our most senior sewers assemble the first sample. We typically deliver this initial prototype within 7-10 days. This stage is pure problem-solving—a hands-on exercise in determining the optimal construction method for your character. For a closer look at the craft involved, our guide on how to sew a stuffed animal provides valuable insight.

Understanding the Different Sample Stages

The sampling process is not a single event but a structured progression. Understanding each stage prevents miscommunication and ensures an efficient workflow.

Mock-up Sample: This is the first physical representation of your design. We often use stock fabrics of a similar weight to quickly validate the shape, size, and overall structure. Color accuracy is not the focus here; the objective is to approve the form.

Pre-Production Sample (PPS): Once the mock-up’s form is approved, we create the PPS. This sample is produced using the final, specified materials, colors, and all decorative elements like embroidery or printed patterns. This is your final opportunity to review the complete look and feel before committing to mass production.

‘Golden’ Production Sample: Upon your approval, the PPS becomes the ‘golden’ or sealed sample. This exact sample is retained at the factory and serves as the ultimate quality benchmark. Every single unit that comes off the production line must match this golden sample perfectly.

From Design Flaw to Manufacturable Product

A design that looks great on paper is not always manufacturable at scale. A crucial function of the sampling process is to identify and resolve these potential issues before they become expensive problems during a full production run.

A common challenge is designs with overly complex geometries, such as characters with numerous small, pointed limbs. While visually appealing, such features are extremely difficult to sew consistently, which significantly increases the cost per unit. During prototyping, we collaborate with you to simplify a curve or enlarge a feature, making the design production-friendly without sacrificing its core identity.

A design is only successful if it can be reproduced consistently at scale. Our role during prototyping is to find that perfect balance between creative intent and manufacturing efficiency, ensuring your stuffed animal toys are both beautiful and viable.

Safety is another non-negotiable element addressed at this stage. Components like small plastic eyes or loosely attached accessories are major hazards for young children and will cause a product to fail safety tests. We immediately flag these risks and recommend safer alternatives, such as embroidered eyes or securely stitched felt details, to ensure your product complies with standards like EN71 (Europe) and ASTM F963 (USA).

Investing time to perfect this prototyping phase is the single most effective way to prevent costly mistakes and delays when producing your stuffed animal toys.

From Blueprint to Bear: A Look Inside the Factory Floor

With the prototype approved, operations shift from the sampling room to the main production floor. This is where your vision is replicated at scale. The final quality of your stuffed animal toys depends entirely on two factors: the raw materials used and the precision of the manufacturing process.

Every superior plush toy begins with high-quality raw materials. The selection of fabric and filling dictates not only the toy’s appearance but also its tactile feel, durability, and, most critically, its safety compliance. Understanding these components is essential for making informed decisions that align with your brand and budget.

The Feel: Choosing Your Core Materials

The primary interaction with a plush toy is touch. This tactile experience is paramount, making fabric selection a critical decision.

Here is a summary of the materials we most commonly work with:

Crystal Velboa (Super Soft Plush): This is our most requested fabric for good reason. Its short pile and extremely soft, smooth finish convey a premium quality, making it the standard for high-end stuffed animal toys for all ages.

Standard Plush: A versatile and cost-effective classic. With a slightly longer pile than velboa, it provides the traditional cuddly feel and is available in a vast array of stock colors.

Minky Fabric: Recognizable by its signature dotted texture, Minky is exceptionally soft and is a popular choice for baby products and toys requiring an additional sensory dimension.

Sherpa Fleece: Designed to mimic the feel of sheep’s wool, this fabric provides a fluffy, cozy texture ideal for specific animal characters like lambs or poodles.

The interior filling is just as important as the exterior shell, providing the toy with its huggable form and resilience.

Our industry standard is Polypropylene (PP) cotton. We classify it by fiber denier—7D/15D PP cotton is a versatile all-rounder—which measures its thickness. This material offers an excellent balance of softness, resilience, and loft, ensuring the toy maintains its shape after repeated compression.

Other options are available. For clients seeking a weighted “beanie” effect, we can incorporate foam beads. For eco-conscious brands, recycled PET filling (derived from plastic bottles) is an increasingly popular and sustainable choice.

This table provides a direct comparison of the most common materials we utilize.

Common Materials for Stuffed Animal Toys: A Comparison

| Material Type | Component | Key Characteristics | Best For | Relative Cost |

|---|---|---|---|---|

| Fabric | Crystal Velboa | Ultra-soft, short pile, smooth finish | Premium toys, characters for all ages | Higher |

| Fabric | Standard Plush | Classic fuzzy feel, longer pile, versatile | Cost-effective toys, wide colour needs | Medium |

| Fabric | Minky | Distinct dotted texture, very soft | Baby toys, sensory-focused designs | Higher |

| Fabric | Sherpa Fleece | Fluffy, wool-like texture | Replicating animal fur (lambs, poodles) | Medium |

| Filling | 7D/15D PP Cotton | Soft, resilient, good loft, hypoallergenic | General purpose, most plush toys | Medium |

| Filling | Foam Beads | Small, firm beads, creates weight & texture | Weighted limbs or bodies (“beanie” feel) | Lower |

| Filling | Recycled PET | Eco-friendly, good loft, slightly firmer | Sustainable toy lines, eco-conscious brands | Medium-High |

Selecting the right material combination is a collaborative process. We guide clients based on their specific design, target demographic, and budget constraints.

How It All Comes Together: The Production Line

With materials selected and inspected, the production line activates. This is a carefully orchestrated process combining modern machinery and skilled labor to produce consistent, high-quality stuffed animal toys.

The first step is cutting. For simple shapes and large orders, we use industrial die-cutting machines, where a custom metal die presses through layers of fabric with high precision. For more intricate designs, we utilize laser cutters that follow digital patterns flawlessly, guaranteeing perfect pieces.

Next, these flat fabric components receive their details. Elements like eyes, logos, or patterns are added using high-speed embroidery machines or various printing techniques (screen or heat-transfer). This is done before sewing, as working on a flat surface is far more efficient.

The detailed panels then move to the sewing department. Here, our skilled team stitches them together, transforming 2D shapes into a 3D form. This is one of the most labor-intensive stages, requiring significant expertise to manage complex curves and seams. For a detailed look at this process, refer to our article on crafting the perfect plush toy.

A common misconception is that stuffing is a simple, one-size-fits-all step. In reality, achieving the perfect density—firm enough to hold shape but soft enough to be cuddly—is an art. We use a combination of machine blowing for the main body and careful hand-stuffing for smaller parts like limbs and ears.

After stuffing, the final seam is closed with a nearly invisible ladder stitch, and any accessories are securely attached. The toy is then brushed and cleaned to remove loose fibers.

Before packaging, every single toy must pass a final, critical test: the needle detection pass. Each toy is conveyed through a metal detector calibrated to find even a minuscule fragment of a broken sewing needle. This is a non-negotiable safety protocol that protects everyone involved.

Why Do We Have a Minimum Order Quantity (MOQ)?

A frequent question from new clients concerns our Minimum Order Quantity (MOQ). This is not an arbitrary number but a practical necessity rooted in the economics of mass production.

We must procure raw materials like fabric and filling in bulk. Our own suppliers have minimums, often requiring the purchase of hundreds of meters of a single fabric color. Furthermore, setting up the production line incurs fixed costs, from creating cutting dies to calibrating machinery. Spreading these setup costs over a larger number of units is what makes the per-toy price commercially viable for our clients.

For most custom stuffed animal toys, a realistic MOQ typically starts in the 500 to 1,000 unit range. This figure is heavily influenced by design complexity. A simple, single-color plush may fall at the lower end, while a complex toy with multiple custom-dyed fabrics and extensive embroidery will require a larger run to be cost-effective.

What Goes into the Price of Your Stuffed Animal Toy?

Let’s dissect one of the most critical aspects of any project: the final price per unit. The quote you receive is a detailed calculation based on factors ranging from fabric choice and sewing time to order volume and required safety certifications.

As a manufacturer, we believe in transparency. Understanding these cost drivers allows you to make strategic decisions to balance your budget with your creative vision for the perfect plush toy.

The Big Two: Materials and Labour

At the core of any quotation are two primary cost drivers: the raw materials we use and the labor required to assemble them. These two elements are intrinsically linked. A more complex design typically requires more varied materials and will invariably demand more time from our sewing team.

For instance, your choice of fabric has an immediate impact. A premium, ultra-soft crystal velboa costs more per meter than a standard plush. Opting for a GRS-certified recycled PET filling over standard PP cotton will also influence the final price.

Labor costs are determined by complexity and size. A simple, round character might be constructed from only six fabric panels. In contrast, a detailed animal figure could have over 30 individual pieces that must be cut, organized, and sewn. More pieces equate to more sewing time, which translates to a higher labor cost per unit.

Size, Detail, and Custom Touches

While it is intuitive that a larger toy requires more fabric and filling, complexity can often have a greater impact on price than size alone. This is where small details accumulate.

Intricate Features: Elements like multi-color embroidery, appliqué patches, or custom-printed patterns necessitate additional machine setups and careful handling. A design with five different embroidery colors will be more expensive than one with a single color.

Structural Elements: Does your toy require an internal wire armature for posability? Will it contain an electronic soundbox? These non-fabric components add to both material and assembly costs.

Custom Packaging: The cost extends beyond the toy itself. A custom-printed gift box or a unique branded hangtag will be factored into the unit price, whereas a simple polybag is the most economical option.

From our factory floor, the truest measure of labour is the number of seam lines. A great cost-saving tip we often share is to see if two small fabric panels can be redesigned into one larger, cleverly shaped piece. You can often reduce sewing time this way without sacrificing the look of the design.

Why Your Order Quantity Matters

The relationship between order quantity and unit price is significant due to economies of scale. With a larger production run, we can amortize fixed costs—such as creating cutting dies, initial machine setup, and project management—over thousands of units instead of hundreds.

This is why ordering 1,000 units will always yield a better price per toy than ordering just 500 units of the same design. It is also why meeting the Minimum Order Quantity (MOQ) is crucial for a project’s financial feasibility.

Finally, compliance costs must be considered. Fees for independent safety testing to meet standards like ASTM F963 (USA) or EN71 (Europe) are an essential part of the budget. Any reputable manufacturer will factor these costs in from the outset. This is a non-negotiable expense that ensures your stuffed animal toys are safe and legal to sell, protecting your brand and your customers.

Getting to Grips with Global Toy Safety and Quality Standards

When creating a stuffed animal, nothing is more important than the safety of the end user. An exceptional design and the softest materials are rendered worthless if the final product is unsafe. For us, ensuring every toy meets stringent global standards is not a final checklist item; it is a principle integrated into our entire production process from day one.

If you are bringing a toy to market, understanding these regulations is mandatory. Compliance is not merely about avoiding legal repercussions; it protects your customers, safeguards your brand’s reputation, and is a prerequisite for retail distribution. This involves a series of rigorous physical and chemical tests that every production batch must pass.

The Big Two: What You Need to Know About ASTM F963 & EN71

While regulations vary by country, the global toy market is primarily governed by two major standards: ASTM F963 for the United States and EN71 for Europe. Although they differ in some specifics, their objective is identical: to eliminate potential hazards in toys.

As a manufacturer, our production lines are engineered to meet these standards from the start. Here is what inspectors test for:

Physical and Mechanical Tests: We subject the toys to simulated real-world use and abuse. Specialized machines pull on eyes, noses, and seams with a specific force to ensure they do not detach and become choking hazards. We also perform drop tests and compression tests to verify structural integrity.

Small Parts Check: Any component that can fit inside a standardized small parts cylinder—a tube designed to mimic a child’s throat—results in an automatic failure. This is why for toys intended for children under three, we almost exclusively recommend embroidered eyes over plastic ones.

Flammability Testing: We test the fabric and stuffing’s reaction to an open flame. The material must not ignite easily, and if it does, the flame must self-extinguish within a specified time.

Chemical Screening: This is a critical laboratory test. We screen for a comprehensive list of hazardous substances, including heavy metals (like lead and mercury) and harmful chemicals like phthalates. Every single component, from the fabric dye to the sewing thread, must be certified clean.

Passing these tests begins with sourcing materials from trusted suppliers who can provide their own safety certifications.

Our Three-Stage Quality Control System

A cursory inspection at the end of the production line is insufficient. Effective quality control is a continuous process integrated into every stage of manufacturing. We employ a three-tiered system designed to identify problems early, thereby reducing waste, saving time, and guaranteeing the quality of the final product.

1. Incoming Quality Control (IQC)

Before any fabric is cut, our IQC team meticulously inspects all incoming raw materials. They check fabric rolls for color consistency against the approved Pantone, verify material weight and feel, and ensure the PP cotton filling is pure white and has the correct loft. Any material that fails to meet specifications is rejected at the source.

2. In-Process Quality Control (IPQC)

Our IPQC inspectors are constantly on the factory floor, monitoring the assembly line. They check sewing stations for correct stitch density and seam strength. They conduct spot-check pull-tests on attached accessories and verify embroidery quality. This proactive approach allows us to correct minor issues immediately, preventing the production of hundreds of faulty units.

3. Final Quality Control (FQC)

Once a toy is fully assembled, it undergoes a final, intensive inspection. The FQC team inspects a statistically significant sample from every batch (or 100% of the units for smaller or highly complex orders). They compare each toy against the “golden sample,” checking every detail from overall shape to hangtag placement. Every single toy also passes through a metal detector at this stage before being packed.

A classic mistake for newcomers is to choose a factory purely on price, only to find out their quality control is an afterthought. A robust, multi-stage QC process like ours is a non-negotiable that protects your investment and your brand.

The final step is independent, third-party laboratory testing. We manage the logistics of sending production samples to accredited labs like SGS or Intertek. They perform the official EN71 or ASTM tests and issue the certificates required for legal sale. This independent verification provides absolute peace of mind for you, your retailers, and your customers.

Finding the Right Manufacturing Partner

With your design finalized and a clear understanding of costs, you face the most critical decision: selecting your factory. This is not a simple transaction but a strategic partnership. The right partner will define the quality of your product, the reliability of your supply chain, and ultimately, your brand’s reputation.

I have witnessed it too often—an alluringly low price from an unvetted factory devolves into a costly disaster of substandard products, missed deadlines, and failed safety tests. Let’s ensure you avoid that fate.

How to Properly Vet a Supplier

When engaging with potential manufacturers, you must ask pointed, practical questions that penetrate the sales pitch. Their responses will reveal their true capabilities.

First, verify their direct experience. Do not just ask if they make toys; request to see examples of stuffed animal toys they have produced that are similar to yours in size, complexity, and materials. This demonstrates their proven ability to handle your specific project.

Next, inquire about their factory certifications. Audits such as ICTI (ethical toy production) or BSCI (social compliance) are significant indicators of a professional and responsible operation.

Finally, delve into the specifics of their quality control. A reliable partner will be transparent and eager to detail their multi-stage inspection process, from raw material checks to final product reviews. If they are evasive about their QC protocols, it is a major red flag.

OEM vs. ODM: What’s the Difference?

You will frequently encounter two acronyms: OEM and ODM. Understanding their distinction is key to defining your project’s scope.

OEM (Original Equipment Manufacturer): This is for brands with a completely unique product concept. You provide the custom design, technical specifications, and all requirements. We act as your manufacturing arm, producing your exclusive product to your exact vision.

ODM (Original Design Manufacturer): This is a faster route to market. You select a design from our existing catalog and customize it for your brand. This could involve new colors, adding your logo, or changing fabrics. It is an excellent strategy to reduce development time and costs.

A good way to assess a manufacturer’s quality and ODM capabilities is to review their range of plush toys for wholesale.

As a factory, we handle both OEM and ODM projects daily. The right choice depends on your business objectives. OEM offers complete creative control and product exclusivity, while ODM provides speed to market and a lower barrier to entry for new stuffed animal toys.

Making Sense of Global Logistics

Once your toys are manufactured and packaged, the final step is transportation from our factory to your warehouse. This involves understanding logistics and shipping incoterms.

You will almost always see pricing quoted in one of two ways:

- EXW (Ex Works): The price covers the product at our factory gate. You are responsible for arranging and paying for all subsequent shipping steps.

- FOB (Free On Board): This is much more common. The price includes the product and the cost of transporting it to the designated port (e.g., FOB Shanghai). Your shipping responsibility and costs begin once the goods are loaded onto the vessel.

For the actual transport, you have two primary options. Sea freight is significantly cheaper for large volumes but is slow (weeks). Air freight is very fast, ideal for urgent deadlines or smaller, high-value shipments, but is substantially more expensive.

Navigating customs can be complex, which is why a reputable freight forwarder is invaluable. They act as your agent, managing all documentation to ensure your stuffed animal toys clear customs smoothly, providing a hassle-free final delivery.

Your Top Questions About Manufacturing Stuffed Animal Toys, Answered

For those new to custom plush toy creation, practical questions are common. Here are direct answers to the most frequent inquiries we receive from our B2B clients.

What’s a Realistic Timeline for a Custom Order?

Once the final prototype is approved, a realistic production timeline is 30 to 45 days for the order to be manufactured, packaged, and ready for shipment.

This period is divided into two main phases: sourcing the specific raw materials for your design (approximately 10-15 days) and the mass production run itself (another 20-30 days). Extremely large orders or highly complex designs may require additional time, and we maintain open communication throughout the process to manage expectations.

How Can We Get the Unit Cost Down?

While material selection plays a role, the most effective way to reduce the per-unit cost is to increase your order quantity. The price difference between a 500-unit run and a 1,000-unit run, for example, can be substantial. This is due to the amortization of fixed costs (e.g., cutting dies, line setup) over a larger number of units.

Simplifying the design is another effective strategy. Reducing the number of embroidery thread colors from five to two, or redesigning a toy to use one larger fabric panel instead of several smaller ones, can decrease both material waste and labor time. These adjustments often have a significant impact on the final price without compromising the design’s core appeal.

We often see newcomers attempt to create a very elaborate first product. My advice? Start simpler. Test the waters with a more straightforward design. You can always introduce more complex features in later runs after you’ve proven the concept and have sales data to back it up.

What If We Discover a Quality Problem After the Toys Arrive?

A reputable manufacturer stands behind its product. Before shipment, we provide a comprehensive quality control (QC) report, including photos, for your final approval.

However, should an issue be discovered upon delivery, we address it immediately. We will request photos and a detailed description of the defect to conduct a root cause analysis.

Depending on the severity of the issue and our contractual agreement, the solution could range from a credit on a future order to a remake of the defective units. This is precisely why partnering with a manufacturer who has a transparent QC process and clear communication protocols is essential for your peace of mind.

Ready to bring your plush toy idea to life with a partner you can trust? FunEnjoy PlushToys offers a complete manufacturing service, focusing on quality and transparency every step of the way.